3/3/2022

THE 6X®: VEGA’s simple radar formula for better processes

VEGA ushers in a new era in level sensing with the radar sensor VEGAPULS 6X.

With VEGAPULS 6X, VEGA has turned the traditional way of choosing an instrument inside out: There is now only one radar sensor – suitable for all applications.

With VEGAPULS 6X, VEGA radar “thinks” in a new way. The result: A new radar sensor that can measure in every conceivable level application. The times when users had to choose the right level measuring instrument from a multitude of different ones are now history.

Traditionally, the search for a suitable radar level sensor begins by asking which frequency would be best for the specific application, or by determining the properties of the medium, the temperature ranges involved and the process fittings required. Until now, choosing an instrument was a laborious task, but VEGA is now transforming the process completely with its new VEGAPULS 6X. “Ultimately, it’s not the sensor that counts, but what the users can achieve with it in their individual processes,” says Florian Burgert, who, as a product manager, has been closely involved in product development from the very beginning. “Just knowing that they’ve chosen the best possible measurement solution and that they’ll reach their goal faster with it makes a big difference in their everyday operations.”

Over 1 million instruments in use worldwide

The success story of today’s world market leader in radar level measurement began 30 years ago, and in the meantime, VEGA’s sensors have optimized millions of industrial processes. The story includes milestones such as the world’s first two-wire radar instrument and the first 80-GHz radar sensor for liquids on the market. Behind this success are the many people who share a common passion: “At VEGA we don’t do a hundred different things, we concentrate on what we do best: radar,” says product manager Jürgen Skowaisa, speaking for all of them.

All-round protection

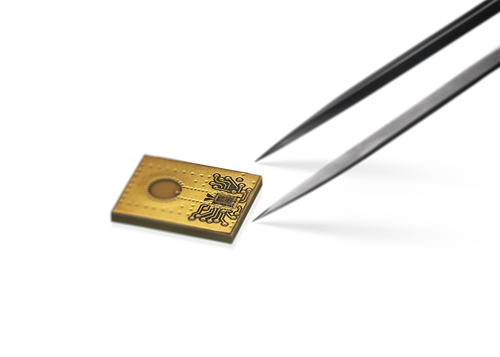

The new VEGAPULS 6X offers the best that is technically feasible today: a self-diagnosis system that immediately detects damage or interference that ensures significantly higher availability and safety, it has new radar-chip technology, with expanded application possibilities and simpler operation. In addition to SIL certification, the matter of cybersecurity has also been fully taken into account: Compliance with security standard IEC 62443-4-2, which specifies the strictest requirements for secure communication and access control.

The value lies in the best application

Level sensors should make it easier for users to monitor their industrial processes. The ultimate purpose of VEGAPULS 6X is: maximum simplification. It is the one sensor that can handle any application. In the future, the customer will no longer have to worry about the technology, frequency or instrument version. Even setup and commissioning has been reduced to a minimum, requiring now just a few clicks and basic application parameters. In many cases, all application-specific settings can be made in VEGAPULS 6X before it leaves the factory. Mount, connect, done: It couldn’t get any simpler.