VEGA's most significant projects already awarded

For a Mega-project or a single measuring point, VEGA gives you the same attention.

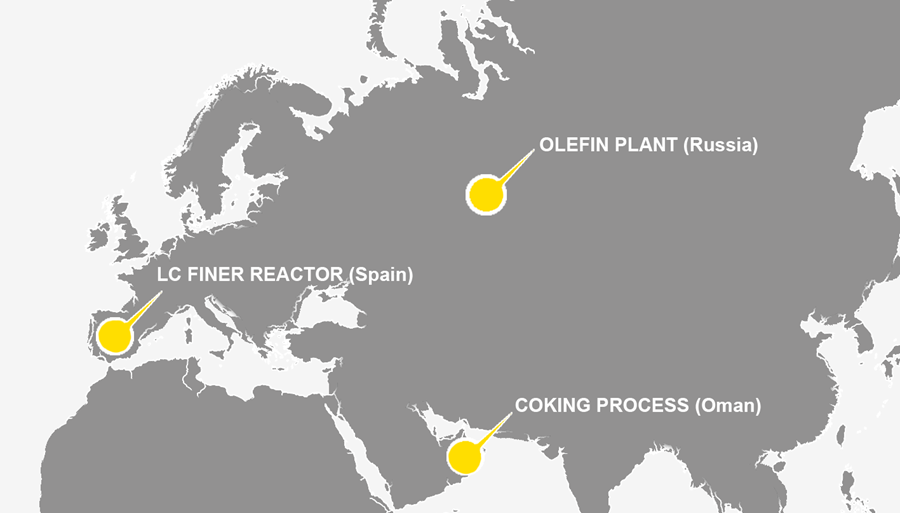

So, as a German International Group located in the Black-forest, we are glad to share with you our 3 significant awarded projects from the last 12 months.

New Olefin Plant in Russia

- Package: a large number of Level Transmitters with external chambers and Level switches for Cryogenic applications ; up to -196°C

- Details of the project:

PJSC Nizhnekamskneftekhim, one of Europe's largest petrochemical companies and a member of the TAIF Group will built it’s new olefin complex to produce 600,000 tonnes of ethylene and over 600,000 tonnes of other chemical products per year. The new plant consists of a naphtha cracker that thermally breaks down hydrocarbon feedstocks – naphtha in this case – into olefins such as ethylene, propene and butadiene.

VEGA's scope of supply is to provide Guided Wave Radars equipped with bypass chambers and Tuning Forks with its unique Low Temperature Design.

Delayed Coker and others in Refinery for Oman:

- Package: Radiation based level gauges with sources and Guided Wave Radars

- Details of the project: Duqm Refinery and Petrochemical Industries Company L.L.C , based in Al Duqm located in the South East Al Wusta Governorate of the Sultanate of Oman, is a Joint Venture (JV) between Oman Oil Company (OOC) and Kuwait Petroleum International (KPI). It is a grass roots refinery which aims to produce light/middle distillates at a high efficiency rate. It focuses on naphtha, jet fuel, diesel and LPG as its primary products. The refinery comprises hydrocracking, hydro-treating and delayed coking units, along with sulphur recovery, hydrogen generation and merox treating units. The refinery will have the capacity to process around 230,000 barrels of crude oil per day.

For this project, VEGA in now in the realization phase and provides a large amount of Radiation based level gauges with sources and several hundreds Guided Wave Radars for various applications.

Hydrocracking Reactor in Spain

- Package: Radiation based level, density and switching of several hydrocarbon & catalyst.

- Details of the project:

To satisfy Compañía Española de Petróleos (CEPSA) aim to strengthen their position as a major provider of marine diesel and bunker fuel oil, CEPSA will integrate 36,700 bbl/d of an innovative process hydroracking technology with 27,600 bbl/d of Isotreating technology. The new process provides high conversion of residues selectively to liquid products with superior performance and reliability which completes the bottom of the barrel solutions to meet future International Maritime Organization (IMO) regulations

Density measurement in the hydrocracker

Radiation-based sensor for density measurement.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}