Replacing displacers: Upgrading to guided wave radar technology eliminates costly maintenance

The cost of waiting to upgrade

We’ve all had that car, appliance, or tool we just refuse to toss out. It works just fine – as long as we keep throwing parts at it. At the time, we rationalize our decision and tell ourselves a new one just isn’t in the budget. Besides, all those quick fixes never take too long. But with each quick fix, the maintenance bills and the time spent continue to add up. Now, the maintenance costs have surpassed what it would have cost to simply make the upgrade.

Many refineries and petrochemical facilities are guilty of this when it comes to their displacer technology. This mechanical technology uses a torque tube or spring-loaded float to measure liquid level or interface. The internal mechanical parts experience metal fatigue, and they require regular recalibration. Displacers are also prone to failure due to vibration, turbulence, or just getting stuck. The amount of time spent cleaning, maintaining, and replacing these instruments adds up.

Retrofitting new technology to replace the old

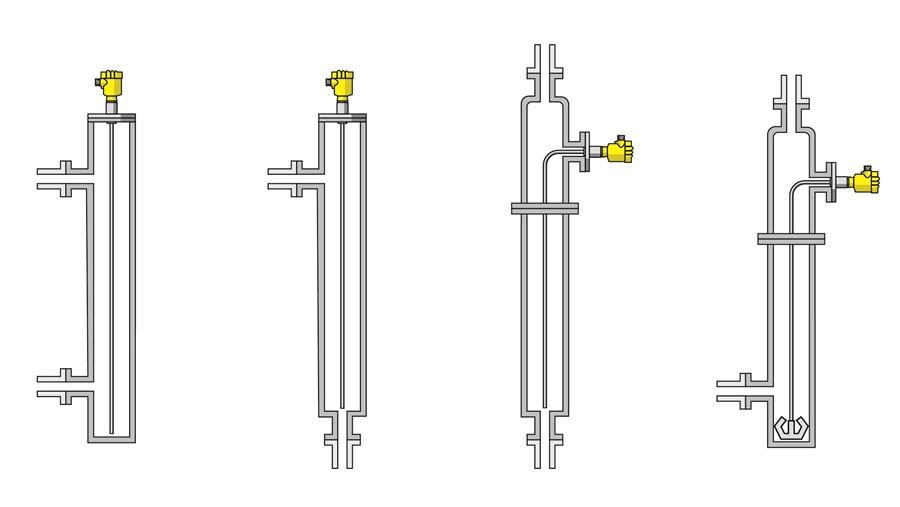

Displacer configurations from left to right: Side-to-Side, Side-to-Bottom, Top-to-Bottom, Top-to-Side

Replacing displacer technology with an electronic sensor alternative is the easiest solution for stopping the merry-go-round of maintenance and cleaning. Installing a guided wave radar in the displacer cage, which resembles a bridle, bypass chamber, or pipe, is mostly straightforward. Not all displacer cages are created equal, however, and retrofitting these instruments with a guided wave radar requires a little bit of creativity and ingenuity.

Displacer cages come in four different configurations: side-to-side, side-to-bottom, top-to-bottom, and top-to-side. Configurations without a pipe coming from the top – side-to-side and side-to-bottom – can easily be retrofitted. It’s simply a matter of removing the displacer electronics and float and installing a new guided wave radar and necessary flange to start receiving a more reliable measurement. The other two configurations containing a pipe at the top require a little more creativity and finesse.

Displacer cages with piping coming in from the top – top-to-bottom and top-to-side configurations – would require re-routing piping and adding a process connection to install a standard guided wave radar sensor. This is an expensive and time-consuming endeavor to install a single sensor. Fortunately, there’s a more economical solution that provides reliable results.

Upgrading pays for itself in less maintenance

A large refinery on the West Coast had been struggling with a failing displacer with a top-to-bottom configuration on their naphtha reboiler. With a total refining capacity of 120,000 barrels per day, they supply supplies gasoline, jet fuel, and diesel fuel to the local transportation market, and they manufacture heavy fuel oils, liquefied petroleum gas, and asphalt for export. Constant maintenance and repairs related to this displacer were adding up, chipping away at the productivity and efficiency of the facility. It was time for a permanent fix.

The large refinery discussed their troubles with VEGA, and the global manufacturer of process measurement technology provided a creative, long-term solution the refinery needed without the need to reconfigure the overhead piping. The VEGAFLEX 81 guided wave radar can be configured with a 90˚ bend in the rod. With this configuration, the piping above and below can remain intact, and maintenance crews only need to install the new guided wave radar where the displacer once was.

Conclusion

Refineries typically have a number of displacers they’re using for level or interface measurements. Those displacers, unfortunately, are mechanical measurements, so even when they’re working properly, it takes a lot of labor and time to keep them reliable and functional. The single displacer at the West Coast refinery mentioned above needed maintenance every six to eight weeks. This additional work adds up quickly.

Retrofitting displacers with guided wave radar sensors requires a fraction of the time and cost of maintaining old displacers. When refineries and petrochemical facilities are willing to pause for a moment and take the long view, they may just find they can get a big return on investing in upgrades today. Newer level measurement technology allows them to operate more productively, efficiently, and competitively for years to come.

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}