VEGAPULS 69 radar level sensor measures the level of wood chips in a bunker |

The location was a special one for VEGA's service team. Here, in one of the largest biomass power plants in northern and central Italy, VEGA sensors were to replace the visual estimations of the biomass supply carried out by the staff. The Bando d'Argenta biomass power plant (FE) is one of the most efficient of its kind, with an installed capacity of approx. 21 MW and a net electricity output of 25 %. The plant is operated by San Marco Bioenergie SpA, a member of the F2i Group. The annual energy output of approx. 176,000 MWh meets the requirements of about 27,000 local inhabitants.

The biomass plant itself consists of two identical production lines that use superheated steam to power a steam turbine connected to an electric generator, as well as several systems for reducing emissions into the atmosphere (including: filters, DeNOx systems, SNCR systems with urea and bicarbonate injections). The biomass used for combustion is of plant origin. It consists mainly of the residues from specially grown plants and the wooden waste generated by the pruning of forests and poplars.

One of the major challenges at the power station was the biomass storage facility, which has enormous dimensions. Previously, the staff at San Marco Bioenergie SpA had to check the biomass stocks by hand, or rather, by eye. This can be done with open bunkers, where wheel loaders push the biomass back and forth, provided the staff has some practice. However, the amount of material ultimately consumed was always just an estimate, and the staff could never be absolutely sure the replenishments would suffice.

Although this method worked for many years, it was unsatisfactory in two respects. For one thing, the total capacity of the biomass storage facility could never be fully utilised. To avoid overfilling, it was better to play it safe by ordering less. And for another, the plant managers thought the operating personnel still wasted too much time trying to figure out how long stocks would last. So they were a long way away from efficient inventory management. That’s why the engineering team was looking for a simple and reliable solution.

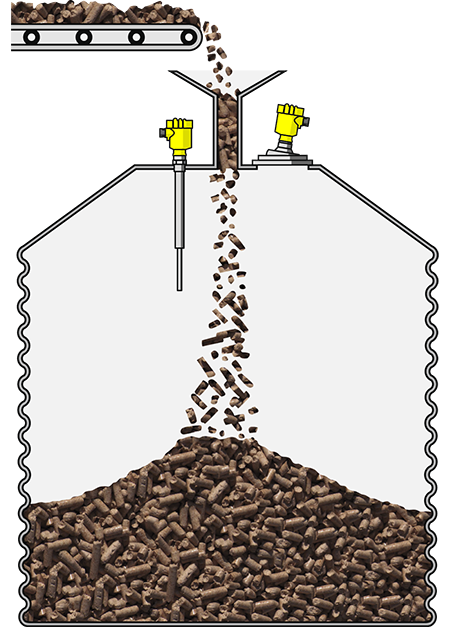

The biomass is stored in the form of wood pellets. These are located in a large bunker measuring 30 x 5 x 8 m. This huge storage capacity is necessary in order to be able to respond to increased demand during the heating season. Furthermore, the power plant process should never be interrupted, and certainly not for lack of fuel. Reliable, accurate measurement of the silo contents was therefore required to enable optimal material logistics planning. The challenge: The operating conditions in the bunker are extremely challenging due to high levels of buildup and dust. From time to time the material is pushed inwards with tractors and tracked vehicles, so there is a lot of material movement as well.

Radar sensor VEGAPULS 69 as a robust solution for level measurement in biomass storage facilities

In the end, two sensors were installed for each bunker. One sensor measures the level from above (i.e. from the roof). The second one measures the horizontal space occupied by the biomass. This makes it possible to evaluate how the bulk solid material has been deposited. It is important to know that the biomass composed of wood chips and pellets is transported to the screw conveyor with the aid of rakes. San Marco Bioenergie therefore wanted to know not only the height of the pellets in the bunker, but also their horizontal distribution.

VEGA took the lead in this project. Yet close contact with and advice from the customer was extremely important. All participants intuitively agreed that two VEGAPULS 69 would be necessary to reliably measure the stock of wood chips and pellets. However, this was completely verified only after the sensors were installed. Today, thanks to VEGA sensors, the supply of pellets to the power plant is guaranteed around the clock. Additionally, the total storage capacity has now been increased without having to invest in new bunkers. And the performance of the instrumentation in daily operation has been impressive. The plant operating team is especially pleased by the fact that the radar sensors work reliably despite extreme buildup and require no maintenance.

Industrial sectors

Related applications

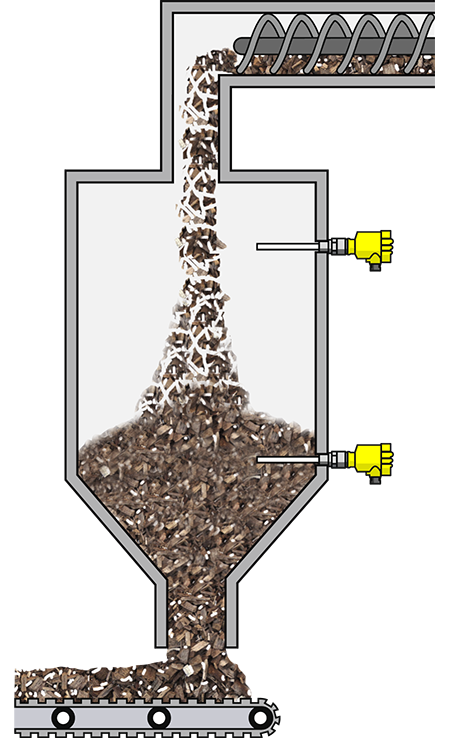

Storage silo for wood pellets

Level measurement and point level detection in a corrugated metal silo

To the applicationDrying facility for wood pellets

Point level detection in front of the wood pellet drying facility

To the applicationWe need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}