IIoT - Collecting sensor information using the Industrial Internet of Things

A case Study with MI Gulf Services

Rod Jones, managing director of MI Gulf Services (one of the leading suppliers of drilling fluid in the UAE and Oman), decided to deploy VEGA’s tank inventory system in one of their remote liquid mud plant.

Their main concern was to improve safety and remove the need for plant personnel to climb up tanks to check stock.

The key operational advantage was having alarms if the tanks were overfilled.

Additionally, by planning production and logistics based on the empty volumes available, a lean production solution was achieved. Following the approach for continuous improvement, Khemraj Ganesh, supply chain manager at MI Gulf Services, not only wanted to equip their liquid mud plant with a safety system, but also insisted on improving services for customers and suppliers using the systems installed.

By providing live inventory stocks to customers, MI Gulf Services was able to establish a transparent relationship. Moreover, with the stock of raw materials now available to suppliers, the company does not expect to run out of products or to be left with unused products. Due to the capabilities of integrating such data to enterprise resource planning, this system provides an electronic trail to verify that all data on the tickets are correct, which was previously done manually. “This system provided live and on the fly data for both MI Gulf Services and our clients, who are mainly operators, so there is absolute transparency with all fluids stored, delivered and received,” says Ganesh. “It also serves as a safety system with the necessary tank alarms.”

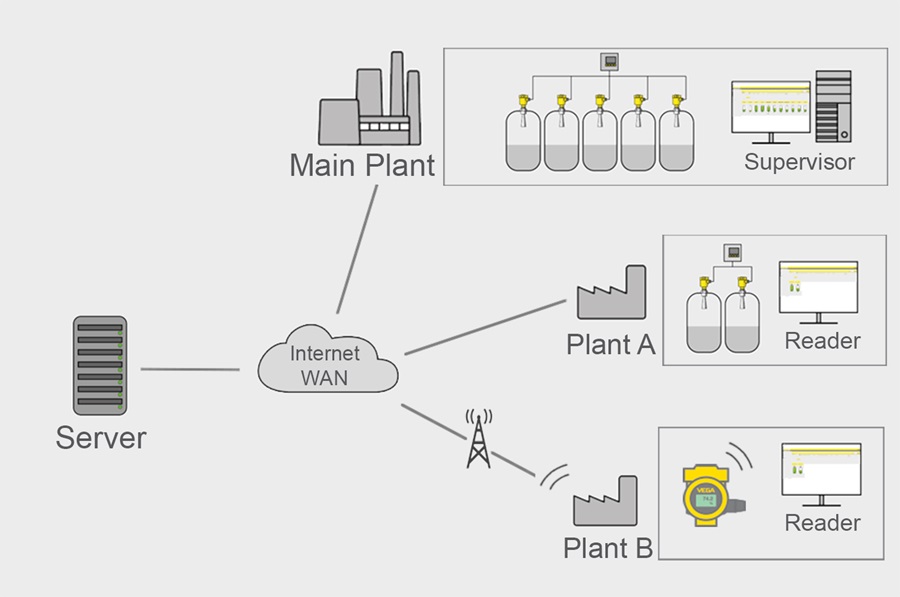

Ingredients for a simple IIoT Structure

Related products

Level transmitter to gauge volume

With today’s technology, products stored in tanks can be easily measured and accounted for with the right sensors. By equipping them with level transmitters, we could measure the level and hence the volume to calculate the stock. Alexis Alexander from VEGA explains: “VEGA would recommend here the VEGAPULS 64 which has an accuracy of +/-1mm, which measures any product irrespective of the process conditions. From experience, the new 80 Ghz radars were developed as a one-for-all sensor to fit any situations like narrow spaces, build-up and foam.”

Mobile Gateway to transmit values

In combination with a level transmitter, a mobile module should be added with the sensor. This would then transmit information to any web browser almost instantly. VEGA offers the PLICSMOBILE T81 with mobile data and GPRS capability, as well as ATEX certification for hazardous areas.

What happens next with the sensor values?

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}