Radiometric Measurements and X-Ray Interference

Radiometric, or nuclear, measurements are made using a radioactive source and a detector. Radiometric sensors have no moving parts, and each component mounts external to the vessel without any contact to the process material being measured or exposure to operational pressures or temperatures.

This low-maintenance, non-intrusive technology provides critical level, density, weight, and mass flow measurements in refineries, petrochemical plants, mines, paper mills, and a number of other heavy industries. Radiometric sensors deliver reliable, long-term measurement solutions where other sensors struggle or fail.

Radiometric method of operation

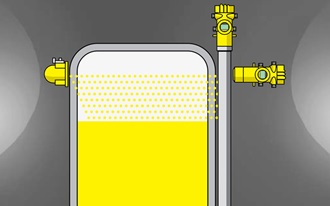

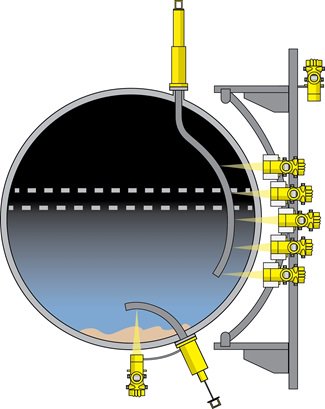

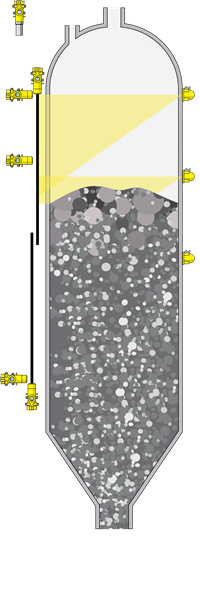

Radiometric systems consist of two parts: A low-activity radioactive isotope in a source holder emits gamma energy through a vessel and a detector mounted on the opposite side measures the radiation reaching it. As the mass between the source and the detector changes – height of level, density of slurry, or weight of solids on a conveyor – the strength of the radiation field at the detector and its registered count rate changes. The sensor electronics can then infer process conditions inside the vessel using the repeatable, predictable change at the detector.

X-rays: When count rates become unpredictable

Some of the same industries using radiometric technology for process measurement also apply X-ray nondestructive testing, or NDT, for weld and vessel integrity inspection. These devices also emit gamma energy from a source holder in a similar fashion to radiometric process measurement instrumentation.

When NDT gamma rays “shine” on radiometric detectors, the radiation field strength and count rate at the detector increase. This outside interference can cause anything from a measurement error to permanent damage to the detector, depending on the strength of the X-rays.

Unfortunately, no two X-ray interference events are the same. Each event is produced using different isotopes, large and varied activity sources, and scans originate anywhere from a few feet from the radiometric detector to hundreds of yards away or even at a neighboring facility. All these variables account for the difficulty in engineering a single reliable solution to the problem.

Solution: A multi-pronged approach

Users must keep three main goals at the forefront when dealing with the potential for X-ray interference. Know when X-rays are present, protect the detector, and continue measurements to keep the process running.

X-ray detection

In an ideal world, interdepartmental communication flows smoothly, and information is shared, recognized, and understood, leaving everyone well-informed. However, it doesn’t always work this way. Communications are never sent, get lost in the shuffle, or they’re forgotten, all of which leave I&E technicians or process engineers unaware of NDT radiography is taking place. An X-ray interference alarm provides another layer of security to alert operators in the absence of other forms of communication.

Count rates registered by the detector increase when X-ray interference is present, because more radiation is reaching the detector. As the count rate increases, the detector will report a decrease in the process value. This can lead to accidental upsets since the default reaction in the control room is to fill the vessel when a measurement drops. An X-ray alarm can prevent this costly mistake, and it can be accomplished in two ways.

Some manufacturers like VEGA provide an X-ray alarm built into their detectors to give operators an invaluable early warning. These alarms work by setting a maximum count rate, the point at which process conditions are at their lowest – i.e. low level or density. Count rates can rise above the maximum during an X-ray interference event, and based on this elevated count rate, it’s possible for the detector’s electronics to trigger an alarm in the control room. The control room can then switch over to manual control, or at least use caution when interpreting the detector’s output.

The first type of alarm works well when X-rays cause excessive interference, but there are instances when the interference is more moderate due to smaller or different types of sources and greater distances from the detector. When there’s enough X-ray activity to cause minor interference, but not push the count rates outside of the normally calibrated span, another solution is needed.

An additional, low-cost radiometric point level switch mounted near the process measurement detector, but outside of the measurement source’s gamma energy beam, is a solution to this situation. This extra detector’s sole purpose is to sense the air for any increase in radiation field strength above the normal background. If levels ever rise above the set point, the control room is alerted an X-ray NDT is occurring. Again, the control room can take the necessary steps to correct for the interference.

X-ray protection

Protecting radiometric detectors from permanent damage is essential to keeping them in good working order for their intended working lifespan. The components inside of radiometric detectors can become prematurely aged and even damaged by exposure to excessive X-rays for extended periods of time.

Nondestructive testing radiography sources are far stronger than the sources used for radiometric process measurement, and these sources can expose radiometric detectors to tens or even thousands of times the field strength in which they’re designed to operate. In these instances, the detectors are at least temporarily blinded, akin to someone inadvertently looking at the sun or directly into bright lights. At most, the detector can become permanently burnt out.

To avoid either of these scenarios or anything in between, it’s best to simply power down the radiometric detector in the presence of excessive X-rays. Some manufacturers like VEGA build in a self-preservation mechanism that automatically cuts power to the photo-multiplier tube when excessive X-rays are detected, then returns to normal operation after the event. This feature can prove to be invaluable for preventing permanent damage to important instrumentation.

Making measurements when X-rays are present

Despite the difficulties previously mentioned, radiometric instrumentation can theoretically still make measurements during NDT X-ray events. These concepts and solutions can work in many scenarios, but none eliminate the issue all together. Because of these exceptions, users need to be aware of how these methods work and their limitations.

Before any interference can be eliminated from a measurement, it must first be identified. With radiometric instruments, there are two methods to accomplish this. The detector can be designed to identify the specific gamma energy coming from the measurement system versus any gamma energy coming from other sources. Alternatively, an identifier can be included inside of the gamma energy coming from the measurement source. Both solutions rely on the detector to recognize an identifying characteristic of the gamma energy emitted, which has little chance of being present in any interference.

Using the first method mentioned, the detector is “tuned” to the energy level of the measurement source isotope. Cobalt 60 is a commonly used isotope for radiometric measurements. Once programmed, the detector will only recognize the gamma energy coming from a Cobalt 60 isotope and ignore any other gamma energy that could potentially disturb the measurement. However, X-ray radiographers use a variety of isotopes, including Cobalt 60, and in these instances, the detector has no way of differentiating the two. Here, reliable measurements aren’t possible during the NDT inspection.

The other, better alternative involves adding a frequency identifier to the measurement source. This is accomplished by placing a rotating rectangular mechanical obstruction in front of the source. The rotation of the obstruction establishes a frequency of gamma ray emission, and the detector can then be programmed to this frequency.

By looking for a specific frequency of gamma ray emittance, the detector can distinguish the gamma ray output of the measurement source from any interfering X-rays. This solution doesn’t work well when the interfering X-ray field strength is too high or too low. Plus, the motorized device, which is continually rotating, requires regular maintenance. Without it, the system can fail, leaving the user with no level control at all. Once again, users should be cautioned about a false sense of security.

Conclusion

When using radiometric instrumentation, X-ray interference may be encountered. There isn’t a single solution to prevent interference or counteract its effects. Knowing how to prepare for it, protect the instrumentation, and work alongside it will best mitigate its effects.

An effective interdepartmental communication strategy is the most effective preparation for when X-ray NDT or other radiography is taking place. In lieu of perfect communications, X-ray detection solutions are available, which can alert control rooms of any interference as it’s happening.

In the case of excessively strong X-ray interference fields permanent detector damage can be avoided by manually powering down radiometric instrumentation or by using detectors with automatic internal power down protection in the event of excessive radiation.

And finally, explore the options for measuring during and throughout any X-ray event, but be aware of the shortcomings to those solutions. There’s not one single answer to every possible scenario, and it’s important to remain diligent and work with your radiometric instrumentation provider to find what works best for your facility.

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}