Radiometric responsibility from start to finish

Radiometric instrumentation lasts up to 30 years or even longer in some cases. These instruments consist of two parts: a source holder and a detector. The source holder contains a low-intensity radioactive isotope, which emits gamma radiation. The detector sits opposite the source holder, measuring the amount of radiation reaching it through the tank, vessel, conveyor, or pipe. The electronics inside the detector use the gamma reading to infer a measurement and output a value.

Once users are finished with one of these instruments, they can’t just toss the radioactive isotope out with the weekly trash. Old sources need to be recycled, reused, or disposed of properly. Some radiometric instrumentation providers like VEGA believe in delivering a solution for anyone who needs to get rid of an old source holder they don’t need anymore. This is a story of how VEGA Americas helped one paper mill dispose of and renew their radiometric sources.

Paper mills’ ups and downs

The digital age has not been kind to the paper industry. Demand for paperwork like order forms, invoices, contracts, and more have dropped since that work can be done digitally. Nowadays, most of these things are filled out and signed online, and the receipts are just e-mailed to us. The need for physical paper just isn’t as high as it used to be. As a result, paper mills across the country slowed down production or shut down all together. It’s just the nature of the constantly evolving way people do business.

Change, however, never stops, and demand for paper is on the rise again. More people shopping online means more items getting shipped, and those things arrive at our doorstep in brown cardboard boxes. Now, paper mills that were once thought to have closed their doors forever are being purchased and placed back into operation, breathing new life into the industry and the communities where they’re located. A Kentucky paper mill recently experienced this rebirth, but it wasn’t as easy unlocking the doors and turning the power back on.

The end of an era

Only a couple years ago, a major paper company made the difficult decision to shut down one of its paper mills. With the paper mill closing its doors, it had to remove any radiometric sources used for measurements. The United States Nuclear Regulatory Commission, or NRC, requires companies monitor and label any radioactive material, so by law, the paper mill couldn’t just leave everything behind. They needed a way to safely and legally remove the sources.

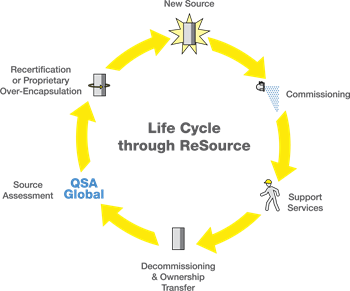

This particular plant had more than two dozen different radiometric sources from four different suppliers. Fortunately, one of those suppliers was VEGA, a company that prides itself on being a complete radiometric measurement solutions provider. Like all other radiometric measurement organizations, VEGA supplies radiometric sources, but they also offer their ReSource® Program, which retakes ownership of radioactive sources used in industrial measurement systems. These sources are then reused, recycled, or properly disposed of.

This particular plant had more than two dozen different radiometric sources from four different suppliers. Fortunately, one of those suppliers was VEGA, a company that prides itself on being a complete radiometric measurement solutions provider. Like all other radiometric measurement organizations, VEGA supplies radiometric sources, but they also offer their ReSource® Program, which retakes ownership of radioactive sources used in industrial measurement systems. These sources are then reused, recycled, or properly disposed of.

Reusing and recycling functioning sources minimizes the amount of radioactive materials being introduced into the environment. Radioactive sources are used in difficult applications where other measurement solutions fail to work, so managing these all-important sources throughout their lifecycle is critical. VEGA was able to enter the recently closed paper mill, safely remove and take ownership of all the radiometric sources, and leave the paper mill in compliance with the NRC.

New life, new measurements, new sources

Roughly two years later, a new company purchased the Kentucky paper mill to meet the increasing paper demands for consumers’ changing habits. To get the operation up and running, they needed instrumentation for roughly a dozen key pipe density measurements. These pipes ranged in size anywhere between two inches up to 22 inches, and all of them still had the old detectors from different manufacturers.

Different manufacturers of radiometric instrumentation all have different philosophies on how measurements should be made. This means the size or type of source can vary from manufacturer to manufacturer. This left the new paper mill owners with a decision to make: go back to the different manufacturers for sources and recalibration, find a single source provider and recalibrate all the detectors, or purchase new detectors with the right size and type of source needed from a single manufacturer to ensure accurate and reliable measurements in every application.

The new owners ultimately decided to work with VEGA to purchase new low-strength sources and new detectors. By purchasing everything new, the paper mill didn’t have to worry about any older detectors no longer working after two years of not being used, and all the sources could be the same size and type. By choosing VEGA, they had the peace of mind knowing VEGA has experience with radiometric technology for every step of the way.

From licensing to removal

Learn more about radiometric instrumentation:

Making paper efficiently and safely

Making paper is no easy task. It involves a number of processes, many of which involve extreme heat, chemicals, or a combination of the two. These factors make monitoring what’s happening in the tanks, vessels, and pipes especially difficult for most process measurement instrumentation. Any technology that comes into contact with the materials used to make paper doesn’t last long. That’s why a lot of paper mills have traditionally used radiometric technology to monitor continuous level, point level, mass flow rates, and density.

Radiometric instrumentation is completely external. It doesn’t interfere with the process, and the process conditions don’t damage the sensor. These instruments are impervious to thermal shock, chemical attack, and other extreme process conditions, and as a result, the sensors last a long time. The isotopes used to make these measurements are typically Cesium 137, which has roughly a 30-year half-life. These sources can outlast the longevity of a paper mill trying to survive in the digital age.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}