Case study: How and why 80GHz level radar is increasing productivity in the screen house at E&JW Glendinning

It's well known that following the extraction and crushing operations of aggregates, the screen house is the ‘engine room’ of a quarry where it processes and grades the aggregates. Its principle function is to sort the sizes of aggregates and ensure the right product is there, ready for coating, stockpiling or direct loading out onto transport. The main process challenges encountered in the screen house are the high dust levels, noise and vibration from the screens themselves and the associated machinery, as well as it being a very inhospitable environment for personnel. At E&JW Glendinning Quarry in Devon, they have installed latest generation of VEGAPULS 69 contactless bulk solids radars, replacing ultrasonic level sensors. This followed the previous successful application of the same radar on the secondary crusher feed hopper level over a year ago, which transformed the reliability and control in that key area of the plant.

What prompted the change? A typical example of these outages; the plant operator would start to load out to a lorry based on the initial level reading of a particular grade, then being unable to complete the loading process due to the bin running empty and the lorry then having to be topped up by a loading shovel from the quarry stockpiles, losing time, making extra traffic movements and taking resources from other areas of the quarry. Then, once mistrust of level readings takes hold, it can be difficult to regain.

According to the user, ultrasonic level sensors were regularly giving false indications thoughout their measurement range, which meant lost time and productivity, both the lorry loading process and infeed control. To keep them working, the original ultrasonic sensors required regular maintenance, cleaning and adjustment with false signal mapping of the silos. Although this may not be frequent to the individual sensors, maybe a few times per year, when multiplied by tens of sensors, along with the associated outages and delays, this really becomes a significant problem.

The materials involved

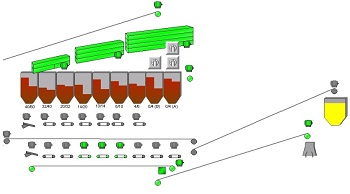

The materials measured are from 0-4mm with very high dust levels inside the bins, to 60mm size where high levels of filling noise can also be encountered. The sensors are deployed across 9 bins (see SCADA image to the right). The plant has a 600TPH load out capacity for road going lorry’s and internal dumpers feed the ready-mix and block production plants. So an accurate ‘picture’ for the operators is a key component for efficient running of the plant.

What about the increased costs and installation?

Radar based level sensors are not as expensive as people think, otherwise they wouldn't be the fastest growing level technology for bulk solids. The price is equivalent to high power ultrasonic sensors, which often get used anyway in applications with high dust levels. So the difference when coupled with the performance increase becomes very marginal. However, the payback from using a more reliable solution can be very quick indeed. The installation in the screen house was easy, the sensors were supplied with flanges to match the current sensor locations and they were able to utilise the same cabling. This new 80 GHz radar innovation also has an extremely capable measuring range span, from just a few hundred centimetres up to 120m, offering excellent versatility for solutions in silos, hoppers, crushers, mobile stockpile levels and even fast change response for conveyor positioning. The sister device an 80GHz radar for liquids, is also suitable for Bitumen tank level.

Why is radar technology better for level in this application?

It uses microwave signals to measure level, they are unaffected by in flight dust, air movement, pressure, temperature or filling noise, that often affects ultrasonic sensors. The new 80GHz radar has excellent focussing too, a 3.5 degree beam angle is typical, so it can easily avoid the build up on the sides of the bins and focus just on the product level, from top to bottom. The higher frequency is also unaffected by even very large amounts of build up from aggregate dust on the transducer face, which again this can quickly attenuate ultrasonic sensor signals. A question regularly asked: Is microwave based radar safe to use? Latest generation radar devices are safe, they conform to EN LPR (Level Probing Radar) standards, so they can be used both inside or outside the plant with absolutely no risks to personnel.

So what has been the outcome for this plant?

Since the installation of the new sensors, Glendinning have seen an increase in plant throughput. The operators are able to control and trim bin levels efficiently. The level increase and decrease is followed in a smoother, more accurate manner, offering a truly ‘analogue or dynamic ‘ representation, rather than a series of jumps and steps they had before. Because there are no false high level alarms, the plant does not unnecessarily place the infeed on hold either, as they are able to trust the levels seen on the SCADA screens. There has been a decrease in the extra traffic movements when directing lorries to the plant or stockpiles, the reduced pressure on stock loader shovels frees them to load the products they are designated for. Of course lower demands on electrical, control and instrument engineers also frees their time for projects and proactive maintenance, as well as reducing risk from working in these areas. They also purchased another set of sensors for the course screens to complete the efficiency improvements across the screen house.

The future?

This site is now also testing a new VEGA innovation: a Bluetooth sensor set up and maintenance tool. Using Smart phone, tablet or PC with Bluetooth, all VEGA devices can be easily and safely commissioned, and simply monitored. The VEGA Tools IOS or Android App can be downloaded for free, and it is low enough cost for any ‘plics’ transmitter (even all those manufactured since 2002) to have Bluetooth capability to securely communicate via encrypted, protected communications. This increases speed of set up and removes the need for personnel to climb silos or work in hostile locations.

No cure, No pay

These new 80GHz radar sensors are excellent problem solvers for almost any liquids or solids level application you wish to name. As a mark of confidence in performance, they are available for test and trail on your application, if they don't prove to be successful solution, you don't pay.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}