Making Shingle Manufacturing a whole lot safer with 80 GHz radar

Making roofing shingles is no easy task, and it can be messy, starting with the very first step in the process. Manufacturers begin with large rolls of fiberglass matte that are fed into a presaturation chamber. Inside, the fiberglass is coated with a hot asphalt mixture heated up to roughly 200˚C. Maintaining an accurate level in the coater pan holding the asphalt is essential to keeping the process running safely, avoiding running dry, and wasting uncoated fiberglass, or worse, overflowing and causing a work hazard in addition to wasting coating material.

Imagine you’re operating this presaturation chamber at a major roofing manufacturer. Your work area is no bigger than a standard cubicle, and your back is turned to the machine while you face the control panel. Getting a reliable level measurement from the coater pan in this presaturation chamber is difficult to say the least. Because of this, you’d experience occasional overflows of the dangerously hot, sticky asphalt just feet away from where you’re working. To add to it, entire sheets of fiberglass would go to waste when the asphalt tray ran dry.

Overflows make for an unsafe workplace

The measurement failures were due to older technology – two thermocouples inside the coater pan. These instruments were susceptible to splashes, leading to false high level readings, and this happened often enough operators grew distrustful of the measurements. This distrust led to dangerous overflows or running dry, which wasted material and time. The manufacturer wanted a safer environment for their employees, so they began the process of looking for a better level measurement solution. Unfortunately, the coater pan is located in a tight space, making it difficult to install any kind of measurement instrumentation. They also needed something that could withstand the extremely hot temperatures and dirty environment inside while still obtaining an accurate, reliable measurement.

The measurement failures were due to older technology – two thermocouples inside the coater pan. These instruments were susceptible to splashes, leading to false high level readings, and this happened often enough operators grew distrustful of the measurements. This distrust led to dangerous overflows or running dry, which wasted material and time. The manufacturer wanted a safer environment for their employees, so they began the process of looking for a better level measurement solution. Unfortunately, the coater pan is located in a tight space, making it difficult to install any kind of measurement instrumentation. They also needed something that could withstand the extremely hot temperatures and dirty environment inside while still obtaining an accurate, reliable measurement.

80 GHz radar makes the job site safer

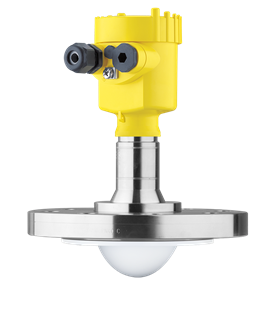

The hot, dirty, and cramped environment inside the presaturation chamber would be a challenge for most level measurement instruments, but VEGA representatives knew an 80 GHz radar could get an accurate level measurement. During a scheduled shutdown, a VEGAPULS 64 was mounted inside the machine five feet above the coater pan. The radar beam was able to shoot between obstructions less than a foot apart because of its focused 3˚ beam angle. The excessive dust, dirt, and oil didn’t interfere with any level readings, and as for the hot temperatures inside the machine, the VEGAPULS 64 is able to withstand process temperatures up to 200˚C. An added bonus – the customer was pleased they were able to use Bluetooth technology for sensor setup, configuration, and troubleshooting, adding another level of safety and security for employees.

The hot, dirty, and cramped environment inside the presaturation chamber would be a challenge for most level measurement instruments, but VEGA representatives knew an 80 GHz radar could get an accurate level measurement. During a scheduled shutdown, a VEGAPULS 64 was mounted inside the machine five feet above the coater pan. The radar beam was able to shoot between obstructions less than a foot apart because of its focused 3˚ beam angle. The excessive dust, dirt, and oil didn’t interfere with any level readings, and as for the hot temperatures inside the machine, the VEGAPULS 64 is able to withstand process temperatures up to 200˚C. An added bonus – the customer was pleased they were able to use Bluetooth technology for sensor setup, configuration, and troubleshooting, adding another level of safety and security for employees.

You can’t put a price on safety, but this sensor pays for itself

This plant has been running more safely and more efficiently since the installation of the VEGAPULS 64. Operators can now trust their level measurement and no longer have to worry about hot asphalt pouring out of the presaturator. The safer work environment provides some additional peace of mind for the company and for its employees.

This plant has been running more safely and more efficiently since the installation of the VEGAPULS 64. Operators can now trust their level measurement and no longer have to worry about hot asphalt pouring out of the presaturator. The safer work environment provides some additional peace of mind for the company and for its employees.

Plus, the plant hasn’t experienced any major losses from wasted material and shutdowns. Before the VEGAPULS 64 was installed, losses from wasted and shutdown time averaged $5,676 every year for the past five years. This is just one of many plants for this customer, and they’re now considering applying the same solution to all of their other plants to provide their employees a safer work environment.

Related industries

Contact your VEGA salesperson for a process instrumentation audit:

Personal consulting

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Fax: +49 7836 50-201

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}