Radar sensors from VEGA ensure accurate metering in lubricant production |

Runs like clockwork

The production of lubricants, printing inks and industrial chemicals requires a lot of skill and intuition. Every product that leaves the Zeller+Gmelin production site in Eislingen, near Göppingen, is individually tailored to the customer. The medium-sized company puts great emphasis on holistic solutions and therefore offers research, development and production from a single source.

In one autoclave at Zeller + Gmelin, temperatures of up to 270° C and pressures of up to 5.2 bar prevail. The apparatus can also contain strong acids or alkalis. Because the measuring instruments in contact with the process quickly reached their limits, an 80-GHz radar sensor was deployed instead, allowing measurement of the level through an inspection glass.

VEGA has been a reliable partner to Zeller+Gmelin for 15 years, always on hand to answer questions concerning pressure and level measurement. Nearly 1,000 sensors are used at Zeller + Gmelin. Almost all of them are visible via VEGA Inventory System, a web-based software for data acquisition and visualisation of level data . This not only makes inventory management possible, these data can also be further processed and used in ERP systems. Zeller+Gmelin also imports the data directly into the SAP system. The data is transmitted directly from the sensor to the cloud, where they are processed by the supplier, who, for example, initiates the delivery of a product.

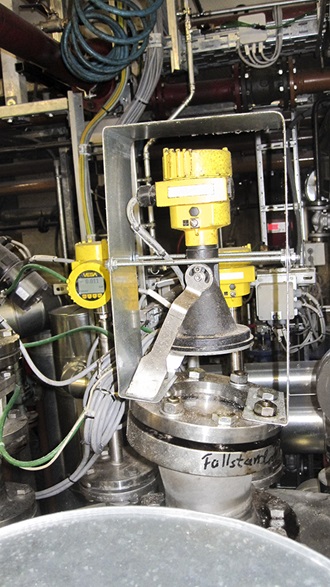

But back to production: In autoclave 3, particularly adverse process conditions are present: high temperatures of up to 270° C, elevated pressure up to 5.2 bar, and the presence of strong acids or alkalis, all of which brings almost any measuring instrument to its limits. In this part of the process, soap is produced. Oil with organic acids and alkalis are filled into the autoclave. There the mixture is stirred and heated under pressure until saponification occurs. Due to these and other additional factors, measurement is anything but simple. The cooking process generates turbulent surfaces, the agitator also causes interfering signals and buildup constantly forms on internals as well as the inside walls of the vessel. As if that weren’t enough, the already difficult measuring situation is compounded by the fact that, due to the internal conditions, an autoclave cannot be opened during an ongoing process. But VEGA had a convincing proposal for this as well: simply measure the level in this vessel through an inspection glass.

In all other production processes, mainly radar sensors with a measuring frequency of 26 GHz were being used. But due to the difficult conditions in the autoclave, the automation team decided to try out VEGAPULS 64, which measures with a frequency of 80 GHz. In particular, its better focusing (by a factor of 3) and greater dynamics promised much.

The reason is that a radar sensor can only detect the level correctly if there is a clear, high-quality level echo. The dynamic range of a radar sensor, i.e. the difference between the largest and smallest signal, determines which applications the sensor can be used in. The greater the dynamics, the wider the application range of the sensor and the higher the measurement certainty. VEGAPULS 64 has a very large dynamic range. This is particularly advantageous when there is foam, condensate, buildup or an extremely turbulent product surface in the vessel, as is almost always the case in an autoclave. Reliable measurement is only possible when there is high measurement certainty. And this certainty allows the level to be accurately measured even when it is very close to the bottom of the vessel. The accuracy is +/- 1 mm.

At the same time, VEGA sensors of type VEGABAR 81 monitor the pressure in the autoclave. A VEGASWING 66 was installed as overfill protection, thus ensuring operation according to AwSV guidelines (systems for handling substances hazardous to water). This vibrating level switch is a master of extremes and therefore ideal for the high temperatures in autoclaves. In contrast to conventional vibrating level switches, VEGASWING 66 has a patented inductive drive that can actuate the tuning fork even under extreme temperature conditions. This means the user can take advantage of the simple handling of vibrating level switches, yet have an extended application range of -196° to +450° C and -1 to +160 bar.

Related industries

Products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}