Raw material silo

Level measurement and point level detection in a raw material silo

Process data

Measuring task:

Level measurement and point level detection

Measuring point:

Silo

Measuring range up to:

10 m

Medium:

Malt, hops and raw fruit sugar

Process temperature:

+3 … +40 °C

Process pressure:

0 … 0 bar

Special challenges:

Dust generation, deposits

Application

Hops, malt and raw fruit sugar are required as raw materials for the brewing process. The raw materials are stored in large silos. To ensure continuous supplies for production are maintained, the level must be constantly monitored.

Your benefit

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Interruption-free production through reliable measurement

User friendly

Maintenance-free operation, unaffected by deposits or buildup

Recommended products

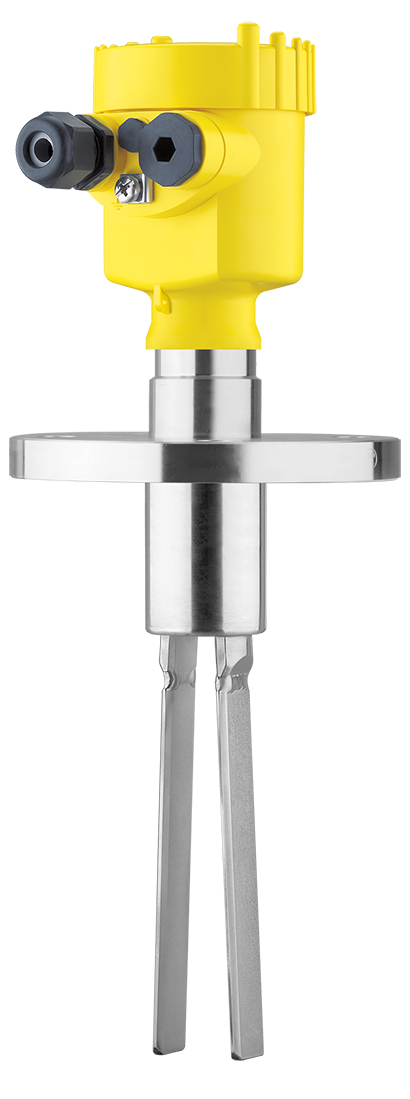

VEGAWAVE 61

Vibrating level switch for level detection in silos

- Reliable detection, even of light bulk solids

- Robust design ensures long service life

- Reliable function due to product-independent switching point

Measuring range - Distance

-

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 25 bar

VEGAPULS 69

Non-contact silo level measurement with radar

- Not influenced by silo internals due to good focusing

- Reliable measurement, unaffected by dust and deposits

- Easy sensor alignment with aiming swivel mounting and VEGA Tools app for smartphone

Measuring range - Distance

120 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

Close