8/4/2020

Ingenious: 3D plant design right from the start

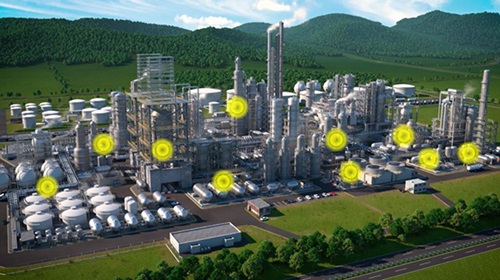

A virtual journey to the optimal level, interface and pressure solutions for refining and petrochemicals

As a specialist in level and pressure measurement technology, VEGA offers ultramodern and extremely reliable solutions for efficient processes in the refining and petrochemical sector. The sensors represent precise and consistent engineering through all important process steps as well as maximised operating margins. A new 3D simulation now provides even deeper insights and a clearer overview.

A walk through a real refinery can be long and arduous. There are often hundreds of metres between the individual process steps. The end products are produced – at the required quality – in processing systems covering large areas: columns, depropanisers, flare systems, retention and condensate tanks . But in order for this to happen, many process steps must first be interlinked: distillation and cracking, desulphurisation, filtration and storage are just a few of many.

Virtual tour

In a typical refinery there are many complex production processes for processing crude oil into higher-quality products. To increase efficiency, throughput must be optimised and regulated more efficiently. How exactly this works in detail can be seen on a tour with the new 3D animation from VEGA. With just a few mouse clicks, visitors dive so deeply into the respective plant areas that they can see in detail how the optimal measurement technology is being used. The simple schematic makes the process stages comprehensible and merges them into a continuous process chain. This visualisation concept is thus able to move part of the actual system planning into the virtual world.

Perspectives for quality

New perspectives always expand the horizon of understanding: The VEGA animations can also help to make planning processes more conceivable and flexible. All application solutions can be visualised, understood and evaluated from a new perspective – for all those involved in planning. VEGA thus provides the basis for seamless integration and easier selection of the appropriate measurement technology. The instrumentation is equipped to withstand the tough environments of the industry, i.e. the extreme conditions of extremes of temperatures, buildup and contamination.

Close