A full-service asphalt paving contractor uses VEGA sensors to keep their plant in tip-top shape

OK Industries has been in business as a full-service asphalt paving contractor. The family-owned and -operated business has locations across Vancouver Island. Whether it is parking lots, highways or airport runways, OK Industries has experienced asphalt and concrete contracting professionals to handle these projects. We had the opportunity to sit down with Ted Harrison of OK Industries.

Ted is a trusted industry advisor, respected for his knowledge and experience. In his existing role he is responsible for automation and electrical projects for all asphalt plants within OK Industries.

What was the problem throughout your process and what were you trying to solve?

What application are you using the VEGAPULS 64 radar sensor for? What are the benefits?

We need to know exactly how many tonnes we have on hand at a plant , which essentially helps the plant operator and the office determine if there is sufficient asphalt oil for the production level. Having the VEGAPULS 64 helps us measure and understand exactly how much asphalt oil we have at any given time.

How are you using the VEGASWING 63? What are the main benefits you have encountered?

We have incorporated them into our offload pump control system to automatically shut off the pump if needed at a safe level. The swing is high temperature rated, compatible with asphalt oil and is reliable.

When was the first time you installed a VEGA radar on site and how long did it last?

We installed a VEGA radar sensor in our largest asphalt tank (115000 gal / 522 tonnes) approximately 10 years ago and it is still running with no issues. We have also used a radar sensor in our 300-tonne natural sand feeder bin and have never had any issues.

What are the main reasons VEGA has worked for you and your process?

Over the past 3 decades I have tried many different types of level sensors and high-level sensors. Most didn’t measure up to what I thought was acceptable until I tried VEGA. They are easy to install, they are designed & manufactured to last in industrial sites & the product support is great. I would not hesitate to buy VEGA’s sensors again.

Applications:

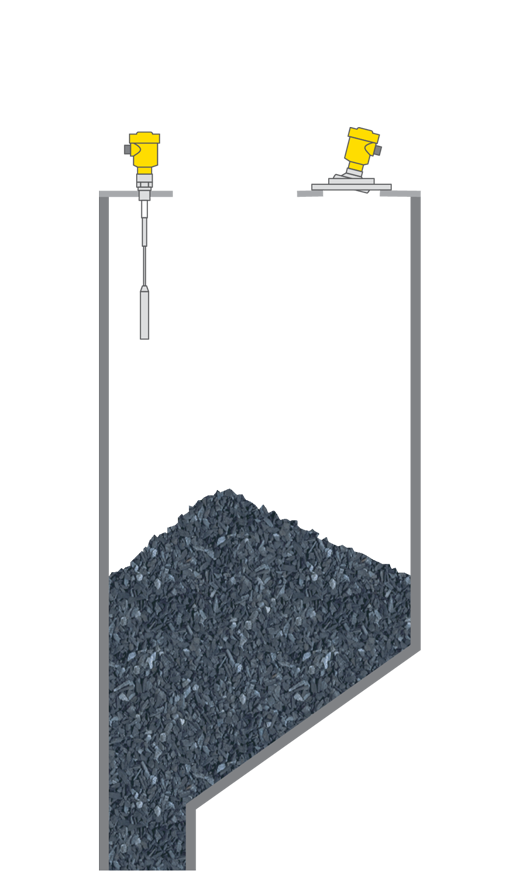

Silo for ready mixed asphalt

Level measurement and point level detection in ready mixed asphalt silos

Different qualities are required from the asphalt depending on the usage and climatic conditions, so every asphalt mixture varies depending on the application. Asphalt is always extremely viscous, hot and highly adhesive. Due to these properties and the numerous different asphalt mixtures, reliable level measurement and point level detection methods are essential.

Reliable

Reliable measuring results even at high temperatures

Cost effective

Optimal utilization of storage capacity

User friendly

Simple installation

Products mentioned in this blog:

Related industries

Building materials

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}