Pump station level measurement: upgrade with 80 GHz Radar

Due to chocked pipes from sewer sludge, Aqualia MACE chose to upgrade the hydrostatic level measurement at ADSSC. Non-contact radars have now improved the reliability in pump control at the busiest part of Abu Dhabi city.

MODERNIZING WATER NETWORKS WITH MEASUREMENTS

Wastewater from households and industrial operations is carried through a sewerage system to the treatment plant. In large sewer systems, the water levels are monitored at key points in the network. Level measurement in the sewer allows an accurate assessment of the degree of utilization of the conduit system.

The Middle East has already modern and well planned infrastructure when it comes to waste water networks. Since the towns and cities are relatively young, the past experiences around the world have been used to develop a modern day infrastructure. Countries in the GCC have developed extensive networks and management systems which are branching out efficiently as the population increases.

The existing networks were developed with several measurement points involving flow, level, pressure and analysers. The level in these sewer networks provides information on the amounts of flow these networks are loaded with. Under ideal conditions, information about the levels give enough data to the operators to make decisions in planning pump and valve controls, and thus to avert an unconformable situation like a flood.

MEASUREMENT TECHNOLOGIES

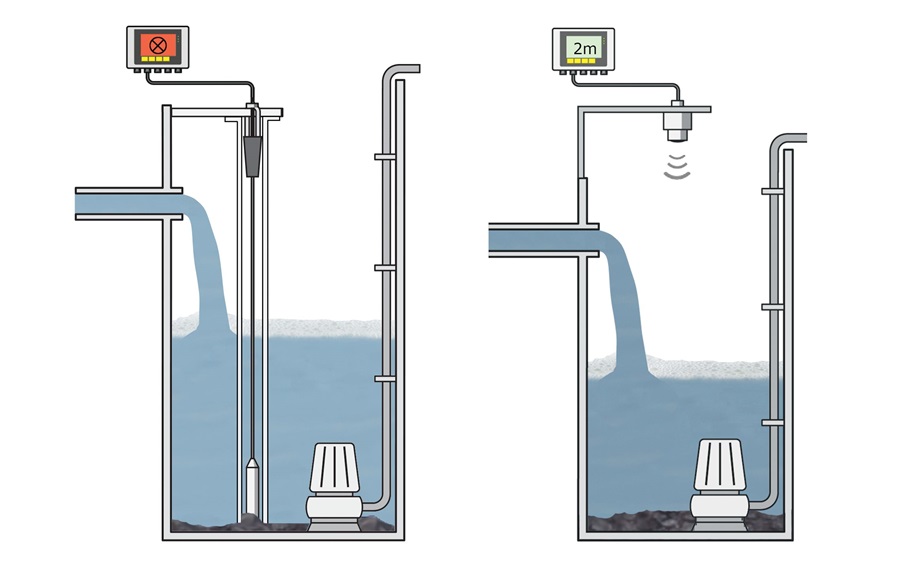

Hydrostatic sensors, like the name suggest, works on the water head pressure it experiences.

The measurement is straightforward and easy to understand: a head pressure of 1bar would relate to a water level of 10 meters.

Without much of a hazzle, hydrostatic sensors can just be dropped to the bottom of a well or in a protective tube to measure the water level. However, conditions in a waste water system are not ideal for such instrument. Sewage networks are filled with both household and sometimes with industrial wastes as well. The chemical composition and the abrasive materials creates a challenge of the seals and diaphragm membrane, which slowly deteriorates creating a sensor failure.

Otherwise, the medium in sewage slowly turns to lumps that builds up chocking the pipes or the sensor and hence blocking the pressure from reaching the diaphragm. Being a contact measurement the diaphragm eventually can get damaged. But the cost versus the ease of measurement makes it an extremely attractive sensor to use till date.

NON-CONTACT MEASUREMENT TO GET RID OF BUILDUP AND CHEMICALS

Non-contact technologies that we usually see are mostly ultrasonic, radar and laser sensors. They sent out a brief ultrasonic, microwave or light beam respectively, and wait for a reflection. The time to send and receive this signal is calculated from the instrument to provide the distance to the product surface.

Now the performance of the instrument will depend on the frequency used.

ULTRASONIC, A FAMOUS NAME BUT FACING RELIABILITY ISSUES

Another limitation of ultrasonic would be condensation and fumes occurring in waste water networks, that would blind or attenuate the ultrasound.

RADAR IS THE BETTER ULTRASONIC

A radar technology would be the apt replacement for ultrasonic in these conditions. Since they are not affected by condensate, build up, pressure, temperature or any ambient or process conditions; radar technology can be used to measure the level in such demanding conditions. All radar manufacturers have given promising results in all water applications. However, due to the lack of price favourable approach in designing these sensors, ultrasonic sensors were still preferred. Moreover the need for a broad antenna for a good focusing, required a large nozzle entry and an area clear of internals that could provide a clear path to the microwave beam. Once the 80 Ghz radar technology available, it was an easy yet confident choice for Aqualia MACE over any other non-contact measurement technology due to the unique and highly improved advantage they presented.

VEGA Grieshaber KG, the German leader for level measurement, is known for the radar level transmitters that they manufacture. They have focused over the years in mastering the technology and have always been the technology leaders in this measurement. The 80 GHz radar have proved it mettle, since it was launched in 2014.

It started off with the VEGAPULS69 measuring bulk solids through extreme dust and built up. Later with the VEGAPULS 64 launched in 2016, most difficult applications in liquid level measurement were easily handled. The instant success gave more reasons for VEGA to offer the same technology for low demand applications like in the water industry at a much lower price.

In 2020, VEGA decided to launch the new non-contact radar by further pushing the already successful 80 GHz radar to a more compact and performant design. The new generations of radars are powered by the 80 GHz technology downsized to a small chip, preserving its unique properties of narrow beam angles and great dynamic range.

Related products

RADAR, A “GO-TO” TECHNOLOGY

If ultrasonic sensors would work in most applications and radars selected only for challenging ones; then today with these low cost high performance radar sensors there is no reason to stay with the ultrasonic technology.

VEGA’s efficiently designed radars for the water market are the better ultrasonics to choose from.

Water network level measurement have sensors installed in humid environments, where the condensation blinds different non-contact technology. As the beams are reflected off from the water condensate ultrasonic, lasers and older radars will show the level as always full. The 80 GHz radar, with the Sensitivity Time Controlled (STC) function implemented, ignores condensates and build ups. Even with extreme environmental conditions from frosting and even surprisingly cobwebs, the radar will continue to measure the real water level easily.

Speaking about, environmental conditions, temperature is a key element in the performance of ultrasonic level transmitters. Every ultrasonic sensor is equipped with a temperature transmitter to compensate the running time of its wave. As temperature changes, the speed of the ultrasound varies which affects the accuracy. A good example to understand it’s importance is a lift station which moves wastewater to treatment plants. A lift station in the Middle East had frequent pump trips due to its level transmitters. The existing ultrasonic sensor, with a range of 8mtrs was set for a measuring span of 800mm. Due to the change in the day night temperature in the middle of the desert, the running time change caused the sensor to drift around the span falsely triggering these pump. A VEGAPULS C21 was used to replace the ultrasonic sensor as it had no effect from ambient temperature conditions.

Sewer pits under manholes during heavy rain can flood quickly if not managed. Level transmitters can be often subject to a hydrostatic head pressure during floods which can result in ingress into the housings and eventually electronic damage. Due to the poor beam angle, ultrasonic sensors had to be installed way below the manhole cover to get a good measurement on the flow channels. But during an event like a storm, these manholes gets flooded causing the sensors to fail. Also as the level moves fast into the dead zones of the ultrasonic, failure or incorrect values are measured and flooding can get unnoticed. The VEGAPULS C series were designed keeping these applications in mind with the encapsulated design and with no dead zones. The encapsulation also allows the VEGAPULS radars to be available with Ex m certification, enabling these devices to be installed in Zone 2 areas without any barriers. As the radar frequency has progressed from 26 to 80 GHz, the beam angled has reduced drastically. On using the models like VEGAPULS C23, the sharp beam angle of 3 degree can also help get rid of such issues allowing us to install the radar at a comfortable distance.

VEGA’s newest generation of VEGAPULS radar level sensors provides the reliability and accuracy operators need for roughly the same price as an ultrasonic device. Each new radar is equipped with Bluetooth allowing a wireless connection with a laptop, smartphone, or tablet. All VEGA devices can be wireless commissioned using the VEGATools app, and if IIOT enabled can be monitored via VEGA’s cloud services.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}