Blast furnace

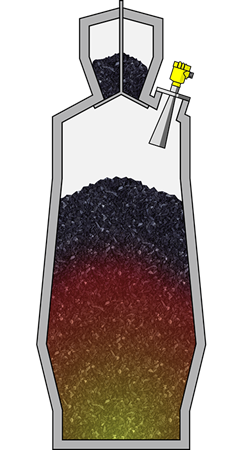

Level measurement in the blast furnace

Process data

Measuring task:

Level measurement

Measuring point:

Blast furnace

Measuring range up to:

20 m

Medium:

Coke, burden

Process temperature:

0 … +200 °C

Process pressure:

0 … +1 bar

Special challenges:

High temperatures, dust generation, filling noise

Application

Burden (iron-bearing materials) and coke are transported from the bunker to the top of the blast furnace. The charging of the furnace is done via conveyor belts or small aggregate wagons. To ensure an optimal distribution of the burden and coke layers, exact level measurement is required.

Your benefit

Reliable

Reliable measurement even during filling

Cost effective

Optimal operation of the furnace

User friendly

Simple mounting and setup

Recommended products

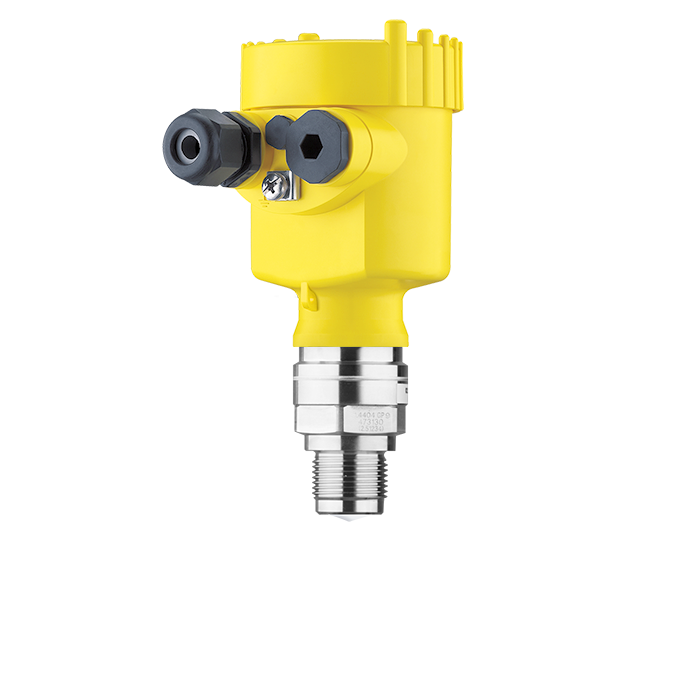

VEGAPULS 6X

Non-contact level measurement with radar in blast furnaces

- Reliable measurement, independent of dust, material composition and high temperatures

- High measurement certainty even during filling

- Wear and maintenance-free Operation

Measuring range - Distance

120 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

Close