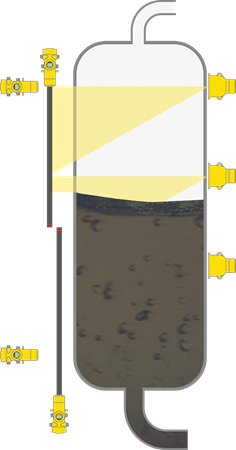

焦炭塔

焦炭塔密度、物位、限位测量

过程数据

测量任务:

密度测量,液位测量,限位检测

测量点:

储罐

测量范围至:

18 m

介质:

重质油

过程温度:

+400 … +480 °C

过程压力:

+3 …+8 bar

特殊挑战:

高温,泡沫多,粘附

应用范围

在石油精炼过程中,延迟焦化装置是十分重要的一个部分,必须尽量避免停机、生产率降低或溢料的发生。焦碳塔高度较高,在运行期间会达到极高的温度。通过对上层气相生成物的密度进行监测,可减少消泡剂的用量。准确测量物位,则能够提升设备利用率。

您的获益

可靠

在极端工况下进行可靠测量

经济

持续监测泡沫层,减少消泡剂用量

方便

安装简便

建议的产品

FIBERTRAC 31

使用同位素仪表连续测量焦炭塔液位

- 仪表设计轻便,无需特殊的安装设备

- 探测器长度高达 7 m,减少额外加装平台的需求

- RS485 串行通信可提供完整诊断,减少故障排查所需的时间

量程 - 距离

7 m

过程压力

-

测量精度

± 0.5 %

MINITRAC 31

使用同位素仪表测量焦炭塔密度及限位

- 非接触式测量,不受介质物理特性的影响

- 通过持续监测,提高消泡剂使用效率

- RS485 串行通信可提供完整诊断,减少排查故障所需时间

- 定时校正实值,测量精准度更高

量程 - 距离

-

过程压力

-

测量精度

0.1 %

关闭