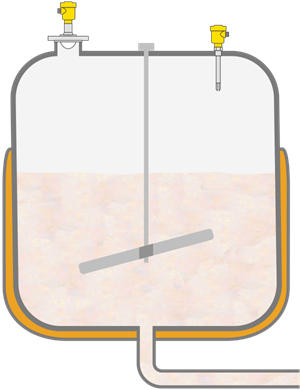

Stirring and batching tank for yoghurt

Level measurement and point level detection in stirred batching tank for fruit yoghurt

Process data

Measuring task:

Level measurement and point level detection

Measuring point:

Tank

Measuring range up to:

10 m

Medium:

Yoghurt

Process temperature:

0 … +135 °C

Process pressure:

-1 … +5 bar

Special challenges:

Cleaning cycles in batch operation

Application

The milk lactose is converted to lactic acid under controlled heating in stirring and batching tanks. This process thickens the milk to yoghurt and gives it its sourish taste. The resulting product is then cooled down. In further processing into a fruit based yoghurt, berries, nuts or grains are added and stirred in. The level and point level detection must be reliably detected to enable optimal filling of the vessel.

Your benefit

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

plics® concept ensures short delivery times

User friendly

Standardised operation of all instruments thanks to plics® concept

Recommended products

VEGAPULS 6X

Level measurement with radar in yoghurt stirring and batching tank

- Non-contact tight focused measurement, unaffected by agitators

- Flange with encapsulated antenna system allows optimal CIP and SIP cleaning

- Reliable volume measurement, independent of changing medium density

Measuring range - Distance

120 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

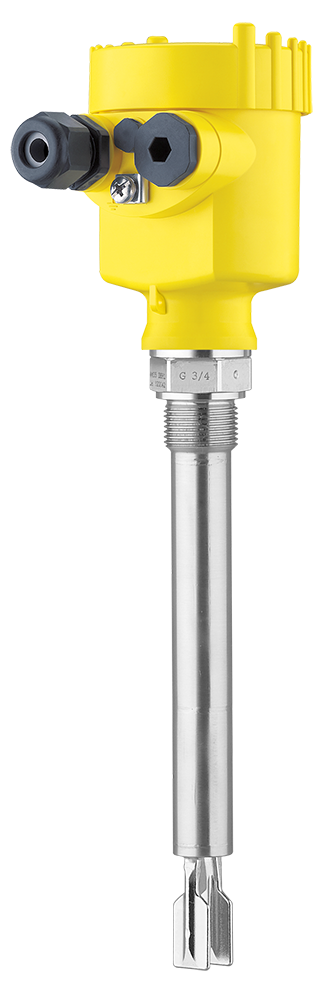

VEGASWING 63

Vibrating level switch as overfill protection in stirring and batching tank

- Product-independent switching point enables accurate and reliable control

- Stainless steel tuning fork unaffected by cleaning processes, abrasion and buildup

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Close