Cables instead of capillaries – electronic differential pressure offers many advantages

Differential pressure measurements are used in many branches of industry for various measuring tasks. Besides mechanical measurements via active pressure lines or chemical seals, electronic differential pressure measurements are now also available. But what is the optimum solution for the user? This article explains the operating mode as well as the differences between the systems. It focuses particularly on the measuring accuracy, delivers decision-making support and gives practical examples.

Operating mode

The mechanical differential pressure measurement always operates according to the same principle independently of its manufacturer: Two pressure values are applied to a differential pressure transmitter. Active pressure pipes or capillaries bring the process so to speak from the measuring point to the field instrument. The measuring cell calculates the difference mechanically which, after transformation, is emitted in an electrical signal and output as a measured value.

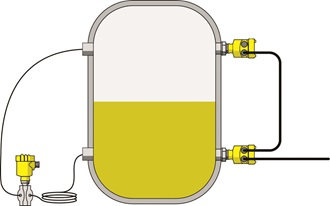

The electronic differential pressure measurement differs: There, the pressure values are measured individually at the measuring points by a primary/secondary sensor pair. The two instruments are electrically connected; the pressure difference is electronically emitted in the primary sensor. The following figure shows the differences by giving an example of a level measurement in a pressurised vessel.

Operating mode

The mechanical differential pressure measurement always operates according to the same principle independently of its manufacturer: Two pressure values are applied to a differential pressure transmitter. Active pressure pipes or capillaries bring the process so to speak from the measuring point to the field instrument. The measuring cell calculates the difference mechanically which, after transformation, is emitted in an electrical signal and output as a measured value.

The electronic differential pressure measurement differs: There, the pressure values are measured individually at the measuring points by a master/slave sensor pair. The two instruments are electrically connected; the pressure difference is electronically emitted in the master sensor. The following figure shows the differences by giving an example of a level measurement in a pressurised vessel.

Operating mode

The mechanical differential pressure measurement always operates according to the same principle independently of its manufacturer: Two pressure values are applied to a differential pressure transmitter. Active pressure pipes or capillaries bring the process so to speak from the measuring point to the field instrument. The measuring cell calculates the difference mechanically which, after transformation, is emitted in an electrical signal and output as a measured value.

The electronic differential pressure measurement differs: There, the pressure values are measured individually at the measuring points by a master/slave sensor pair. The two instruments are electrically connected; the pressure difference is electronically emitted in the master sensor. The following figure shows the differences by giving an example of a level measurement in a pressurised vessel.

Applications and operational conditions

A typical application for differential pressure is the level measurement in pressurised or vacuumed vessels. These may be filling tanks in breweries, stock deaerators in the paper industry, reactors in the chemical industry or condensate collector tanks in power plants. Another area of application is the flow measurement in pipelines via orifice plates or pitot tubes.

It is often used in the steam generation and distribution or in the biogas production. The differential pressure measurement between input and output for the monitoring of any occurring contamination of the filters or function and wear of the pumps is also widely used.

The requirements and operating conditions for pressure measurements can be very different: high static pressures up to 9.140 psi (630 bar), minimum pressure differences of a few mbar, high process temperatures up to 750 °F (400 °C), strong temperature fluctuations, extreme continuous vacuum, suction and pressure surges, abrasion by the measuring medium.

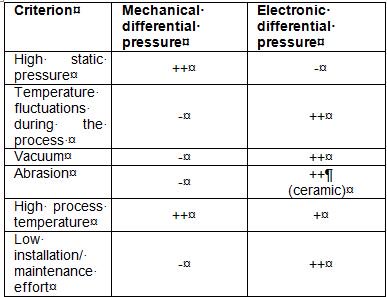

Selection of the measuring system

Application example in the pharma industry

Solvents for the active ingredient extraction are recovered in an approximately 80 ft (2.5 m) high distillation tank by evaporation at around 120 …140 °F (50 … 60 °C) in the high vacuum of approximately 0.75 psi (50 mbar abs).

Mechanical differential pressure systems with chemical seal systems and capillaries were previously used with this kind of application. The high vacuum and the temperatures, however, resulted in degassing of the filling oil and thus to a measured value drift. The measurement only achieved short service lives and quickly became unusable.

Electronic differential pressure, on the contrary, does not require any laying capillary lines. The oil-free ceramic measuring cell also operates reliably and in the long term with vacuum even at high temperatures and without any drift.

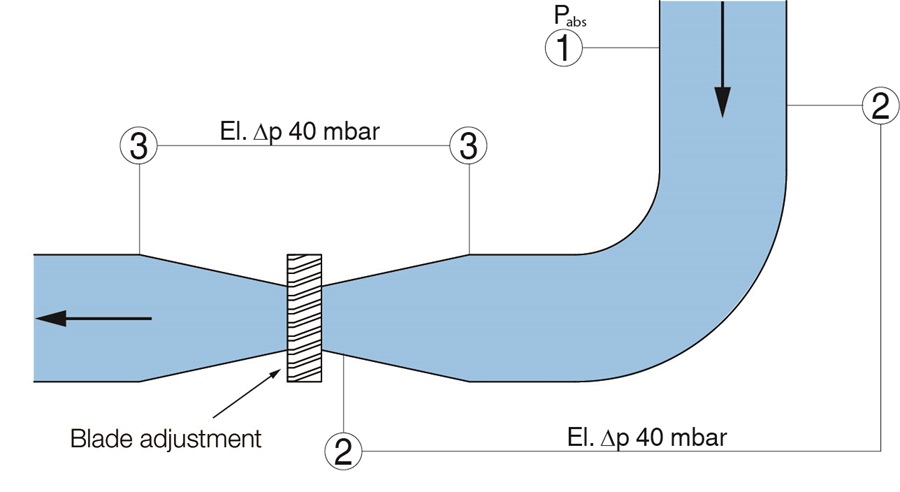

Application example in the power generation

These are usually realized via differential pressure transmitters with small measuring ranges and long pulse lines. This results in a high installation effort, a measured value drift due to temperature influences and blockages by dust and condensation formation. Another disadvantage is the poor access during the regularly due maintenance operations.

With electronic differential pressure, on the other hand, the sensors are directly placed at the measuring points. There is no need for laborious laying of pulse lines. Moreover, the expenses for the required additional heating can be saved. The oil-free ceramic measuring cell works reliably and in the long-term without any drift independently of the ambient temperatures. Thanks to the ceramic measuring cell, no cleaning or maintenance work on the sensor are required.

Application example in the district heating network

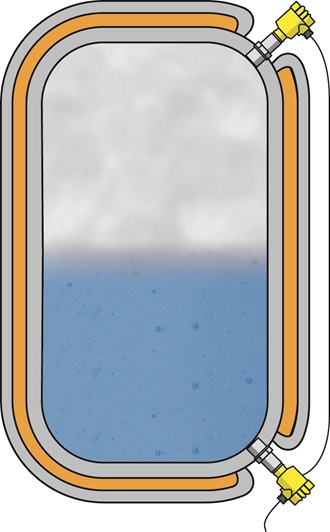

In district heating grids several compensation tanks with a height of approximately 70 ft (21 m) assist with maintaining the pressure. They compensate any leakages as well as temperature-related volume fluctuations within the grid.

The necessary level measurement, until now, was realized via differential pressure transmitters with flanges and long capillary lines. These were laid outdoors and equipped with an additional heating system. For the total pressure to be measured in addition, another sensor needed to be installed.

The electronic differential pressure measurement on the other contrary is significantly less expensive and easier to handle. All the desired measured values can be transferred to the control system. An additional sensor for the total pressure is not required.

Conclusion

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}