A Clean Switch

Thanks to radar sensor VEGAPULS 64, fast batch changes in hygienically demanding processes are now possible

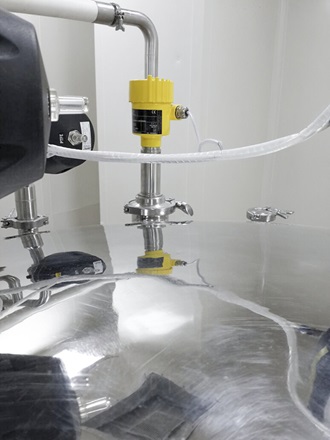

Pharmaceutical vessels are rather small compared to those in the chemical industry. Even at Adam Fabriwerk they usually reach a height of only 1.20 m.

The company of course already knew about the advantages of radar level measurement technology. After all, the method is not only very accurate, but it also measures independently of temperature and pressure as well as the density of the liquid. What is more, the measuring instruments can be easily and quickly installed and put into operation. The most important aspect in pharmaceutical applications, especially in view of the large agitators: the sensors measure contactlessly.

Up to now, Adam Fabriwerk made do with differential pressure transmitters in the stirring vessels. However, in their customers' everyday production this often resulted in measurement uncertainties, for example when the density of the media changed. Especially for pharmaceutical and cosmetics companies, who change media frequently in their process vessels, this presented additional challenges because the vessels require correspondingly frequent cleaning cycles. Also impractical was the necessary calibration, which also led to inaccurate readings.

Once installed, radar sensor VEGAPULS 64 didn't need to be reconfigured, not even during CIP cycles. This has a particularly positive effect when the vessels are delivered to the pharmaceutical manufacturers. The sensors can be adjusted and adapted to the vessel before delivery. The end customer thus receives a fully operational system.

Adam Fabriwerk was enthusiastic about the uncomplicated collaboration with VEGA and the simple installation of the new sensor.

Small containers

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Discover more application examples

Pharmaceutical

Chemical industry

Food industry

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}