Safe Measurement Technology for Hydrogen Applications: What does it come down to?

Why does measurement instrumentation play a decisive role in hydrogen technology?

How is hydrogen produced?

Hydrogen is produced in a variety of ways, with measurement technology playing a central role in all processes.

Steam reforming – the conventional method

Currently, most of the hydrogen produced worldwide is obtained through steam reforming of natural gas. In this process, methane is reacted with steam at temperatures of around 800 °C, producing hydrogen and carbon dioxide. This process is well established, but generates considerable CO₂ emissions – the hydrogen produced is called “grey hydrogen”. If the CO₂ is captured and stored or used in some way, the hydrogen produced is referred to as “blue hydrogen.”

Electrolysis – the climate-friendly alternative

Electrolysis is increasingly being used to produce climate-neutral “green hydrogen". In this process, water is split into hydrogen and oxygen using electricity from renewable sources (e.g., wind, photovoltaics, hydropower). The technical requirements vary depending on the process:

- Alkaline electrolysis (AEL): Uses a potassium hydroxide solution as the electrolyte and requires unvarying operating conditions.

- PEM electrolysis: Uses a polymer membrane and allows for rapid load changes, making it well-suited for fluctuating renewable energy sources.

- High-temperature electrolysis (SOEC): Achieves particularly high efficiency through operating temperatures above 1000 °C.

In all electrolysis methods, precise level measurement for electrolyte storage, pressure monitoring in gas pipelines as well as limit level detection are essential to ensure stable operating conditions.

How is hydrogen transported and stored?

Because gaseous hydrogen has a low energy density, highly efficient storage and transport solutions are required. The choice of suitable methods depends on factors such as transport route, efficiency and safety requirements.

Pressurised storage

The most common storage method is compression in pressurised tanks. Hydrogen is compressed to up to 700 bar and stored in special containers made of high-performance materials. This technology is used in fuel cell vehicles, among other applications.

The main technical challenges in pressurised storage include the need for high precision, in order to avoid overpressure or underpressure, and hydrogen diffusion, which can cause leaks over time. The high-pressure transmitters used here must be resistant to embrittlement.

Liquefaction

In order to transport large quantities of hydrogen efficiently, the gas is cooled down to temperatures between -240 and -253 °C and liquefied. That reduces the volume considerably, but it is an energy-intensive process that requires around a third of the stored energy for cooling. These extremely low temperatures place special demands on pressure transmitters. It also means that the highly insulated cryogenic tanks used for this purpose must be continuously cooled and monitored to minimise evaporation losses.

Chemical storage

A promising alternative is the chemical bonding of hydrogen in carrier substances such as ammonia (NH₃) or methanol. These can be transported using existing infrastructure and converted back into hydrogen when needed. Here too, reliable pressure and level instruments play a key role in ensuring efficient storage and distribution.

What are the challenges when measuring hydrogen?

Hydrogen embrittlement of metallic components also makes robust materials such as stainless steel 316L or special coatings necessary. And for good measure, VEGA relies on diffusion-tight, high-pressure fittings to ensure that instruments work reliably even under extreme conditions.

Which measurement technology is suitable for hydrogen applications?

VEGA offers specially developed instruments that meet the extreme requirements of hydrogen systems:

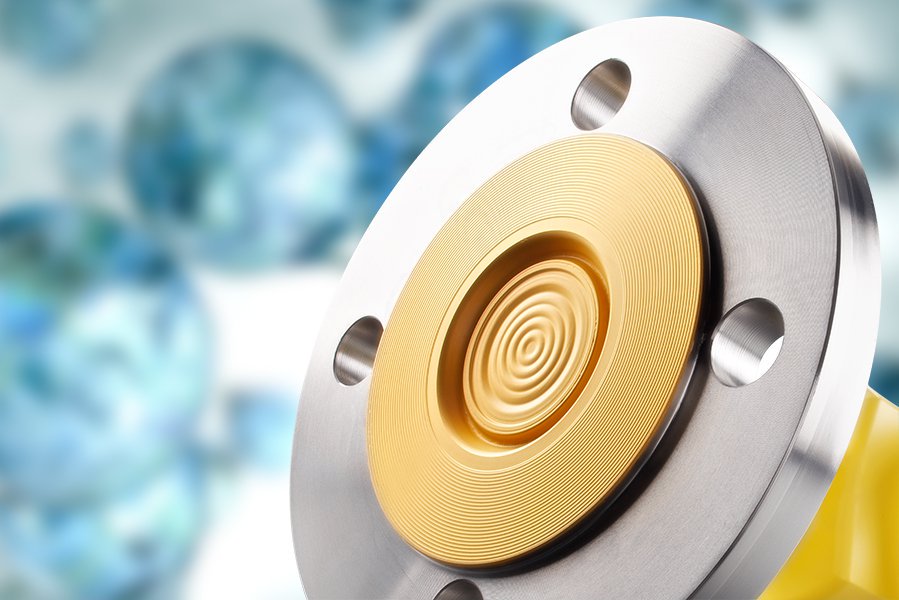

- VEGABAR 83: With a dry strain-gauge measuring cell, this pressure transmitter remains stable for pressure measurements even at extreme process pressures up to 1,000 bar.

- VEGABAR 82: With its oil-free, ceramic measuring cell, this instrument measures gaseous hydrogen extremely reliably and accurately. The measuring cell is also resistant to aggressive media such as potassium hydroxide solution, which is used in electrolysis.

- VEGAFLEX series: Reliable level measurement even in applications with low dielectric constant.

- VEGAPULS 6X: High-precision radar level measurement, e.g. for measuring electrolytes in hydrogen production.

- BASIC instrument: For less demanding peripheral applications, VEGA also offers BASIC instruments that enable reliable and economical measurement of pressure and level in hydrogen plants.

Precise measurement technology for a safe and secure hydrogen economy

VEGA offers customised solutions with metallic or ceramic measuring cells, diffusion-protected fittings and high-pressure instruments that have been specially developed for the extreme requirements of hydrogen applications. This makes it possible to utilise hydrogen optimally and safely as the energy carrier of the future.

Related industries

Hydrogen

Products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}