Measuring rock flow on a conveyor belt: Application of the Month

Ready-mix plants all over southern California rely on a steady supply of crushed rocks to make their product. A nearby quarry meets that demand by extracting rocks and stones from an open pit mine, crushing them, and distributing them to their customers. Processing these rocks to get them to the right size requires moving them to different processes, and this is done along conveyor belts.

To control the flow of materials, operators need to know just how much rock is moving along these conveyor belts. However, getting this measurement can be a challenge for a number of reasons, including excessive vibrations, rocks damaging equipment, and varying belt tensions. The most common answer to achieving this measurement has been load cells, which weigh the rock as it moves along a section of the conveyor belt.

The quarry in southern California had been using load cells, but the maintenance and recalibrations were constant. Plus, the load cells weren’t able to deliver the measurement data to their control system at the operations center. The quarry wanted a better solution – one with less maintenance, fewer calibrations, and a sensor that could deliver the information they need to their control systems.

Non-contact measurement rocks

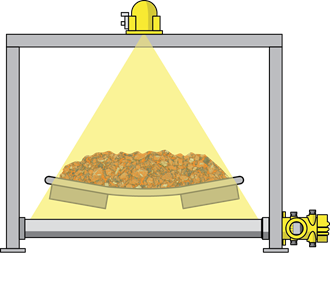

The VEGA WeighTrac 31 uses radiometric technology to calculate the mass flow of bulk materials like rocks in a quarry. It works by mounting a sealed, low-intensity isotope in a source holder above the conveyor belt with a scintillation detector mounted below. A fan-shaped collimated beam of radiation is transmitted from the source through the process material and the conveyor to the detector.

As radiation passes through the matter, its field weakens . As the total mass per square foot changes, the amount of radiation reaching the detector changes inversely. In other words, the amount of radiation reaching the detector is inversely proportional to the amount of material on the conveyor belt. The internal electronics can then use the speed of the belt to calculate the mass flow of rocks or other bulk solids being transported.

The WeighTrac 31 is a completely non-contact measurement, so it doesn’t interfere with the conveyor belt, making installation easier. It’s a solid state system, with no moving parts, so it requires dramatically less upkeep than load cells – no more regular recalibrations. Its resistance to vibration and the metal housing’s ability to withstand most rocks that may fall off the belt all add up to maintenance calls becoming a thing of the past.

Getting all the information in one place

The quarry had a better, more reliable way of seeing just how much rock was moving around, but they still needed to see that information in one spot at their control center. To do that, they input the information from the WeighTrac 31 into a VEGAMET 625, which output the information to their control center using Ethernet. Now, belt speed and the flow of materials can all be seen and controlled from a single location, securing the steady supply of crushed rocks for ready-mix plants all across southern California.

Products in this article

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}