Finding the right sensor for scrubber systems

A global manufacturer of specialty chemicals with over 100 facilities and around 8000 employees, hosts a specialized facility in Bowling Green, OH, that produces a variety of chemical surfactants used in cleaning chemical production. This 60,000 sq ft plant, with between 40-50 vessels indoors and around twelve vessels outdoors, requires precise measurement for their scrubber systems to function efficiently and effectively. Maintaining consistent process conditions was always a concern, and plant operators needed to find a sustainable solution they could rely on.

Where traditional gauges fall short

A smarter differential pressure device

Plant operators held a discussion with VEGA to see what could be done, and based on their current concerns, the VEGADIF 85 was proposed to replace the local gauges. The customer was able to get the new sensors installed and operational within the process upgrades timeline, and the intuitive programming through Bluetooth connection made short work of commissioning of the measurement.

The relatively small size of the VEGADIF 85 allowed them to be mounted in the space available in the plant without major modification or long impulse line runs. With a true instrument and output to the PLC control system at their disposal, plant personnel were able to remotely monitor the system performance in the PLC, get accurate DP readings, and be notified if any troubles in the process were to arise.

Plant personnel were impressed with the high reliability and accuracy of the sensors through their integrated overload diaphragms. With a direct connection to their PLC control system, operators no longer needed to get close to the device to check the current pressure reading. This, in turn, gave them more efficient process control and more throughput, and with precise measurements, plant personnel were proud to report following EPA compliance regulations for the scrubber system and atmospheric discharge.

The VEGA difference for scrubber system differential pressure

The VEGADIF 85 was the right sensor for the right job at this global chemical manufacturing facility. The VEGA differential pressure transmitters’ accurate measurements mean less time spent troubleshooting and second-guessing organizational throughput. Now, plant operators can remotely monitor and manage the blender, atmospheric, and vacuum scrubber processes at the same time. Data is now integrated into the PLC for trending capability, allowing for better process control and increased product throughput.

In the long run, more accurate measurements to report to the EPA means a cleaner environment and atmosphere. And, if personnel ever have any questions or concerns, VEGA’s support team gives them the peace of mind they’re seeking with 24/7 support.

Like other global manufacturers, process automation makes sense to run safer, more efficient, and more profitable operations. Dependable, accurate, and reliable measurements make all the difference between you and your competition. That’s why this plant chose the VEGADIF 85 for differential pressure measurements.

Related industries

Chemical industry

Related applications

Gas scrubber

Level and pressure measurement in gas scrubbers

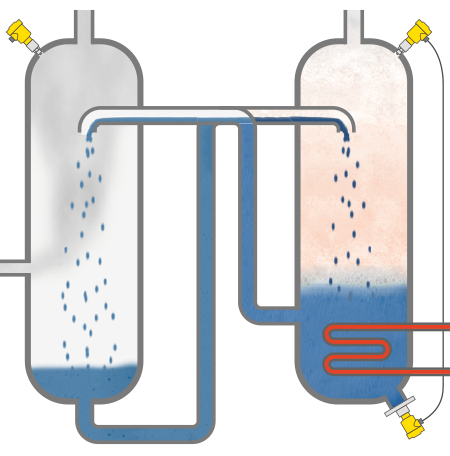

Carbon dioxide is separated from a gas mixture via two scrubbing columns. The gas mixture consisting of nitrogen, hydrogen and carbon dioxide passes through a gas pipeline into the first stage gas scrubber. An added solvent, usually aniline, binds with the carbon dioxide, which is then forwarded in liquid form to a gas scrubber or ‘desorber’ where it is “washed” out of the liquid. The process pressure is monitored during the absorption process, which takes place at high pressure and low temperature. The actual separation of the carbon dioxide from the liquid, however, is carried out under low pressure and high temperature, where the level of the liquid needs to be kept as constant as possible.

Reliable

Reliable measurement, independent of the process conditions

Cost effective

Resistant materials deliver long service life

User friendly

One sensor, two measured values: ceramic cell measures temperature and pressure

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}