State-of-the-art measurement technology for safe chemical logistics: VEGA equips new chemical tank farm with instrumentation

Two million litres under precise control thanks to smart measurement technology

With a storage capacity of 2 million litres, distributed across 40 tank chambers in 22 above-ground tanks, the new tank farm at Friedrich Scharr KG is a high-performance centrepiece of the company’s chemical logistics operations. A wide variety of water-polluting substances, such as solvents and fuels, are stored and processed there.

A fully automated filling system for all types of containers and a 15,000-litre mixing tank for customer-specific solvents round out the existing infrastructure. During construction of the new tank facility, special requirements like earthquake safety and the placement of storage containers on multiple floors of the building had to be taken into account. The aim of the project was to improve economic efficiency, maximise plant safety and minimise environmental impact. These requirements are being met thanks to the use of advanced level measurement and pressure measurement technology from VEGA.

Efficient chemical logistics thanks to integrated process monitoring

The new chemical tank farm at Scharr is equipped with around 170 VEGASWING 63 vibrating level switches, which protect the tanks from overfilling and leaks.

VEGA supplies key technology for the tank farm

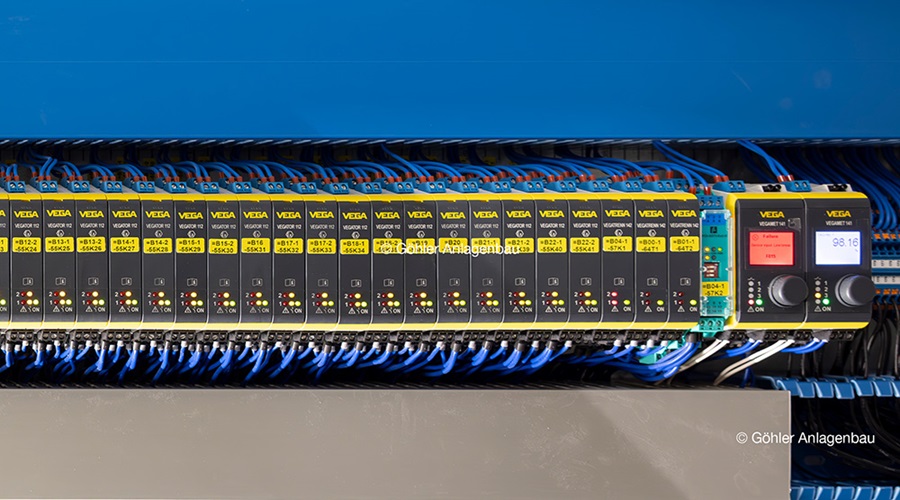

WHG testing of overfill protection devices is considerably simplified by the use of VEGATOR controllers.

For precise level monitoring, overfill protection and early leak detection, the company relies on advanced measurement technology from VEGA. Among other instruments, around 170 vibrating level switches of type VEGASWING 63 and 40 continuously measuring radar level sensors from the VEGAPULS series have been deployed. These not only enable continuous level measurement, but also provide reliable overfill protection in accordance with WHG (German Water Resources Act).

The heart of the system: A VEGATOR controller installed in a switching cabinet, which allows the sensors to be tested centrally without having to access hazardous areas. The central VEGATOR controller transmits NAMUR signals (IEC 60947-5-6) and provides a relay output for the VEGASWING, VEGAVIB and VEGAWAVE vibrating level switches.

This effectively moves the test button for the function check from the level switch on the tank to the controller in the switching cabinet, where a simple WHG-compliant function check can be carried out at the touch of a button, allowing all sensors to be tested centrally. And all of this without having to apply time-consuming and costly methods, such as filling the container to the response level during operation or manually checking the individual probes by dismounting them, an action that can also be extremely dangerous.

The use of VEGA instrumentation therefore not only saves time and money, but also increases occupational safety. This represents a huge advantage in plant operation, especially in the hazardous areas of chemical plants, where many sensors are installed.

Flexible sensors for maximum safety

State-of-the-art level measurement technology

The tightly focussed measuring beam of the VEGAPULS 6X radar level transmitter with 80-GHz technology allows installation with small process fittings.

The VEGAPULS radar sensors installed utilise 80-GHz technology, which offers numerous advantages: They require only small process fittings (e.g. 1.5-inch thread), which allows flexible integration. Thanks to their narrow beam focussing, they deliver exact readings even in tanks with agitators or internal fixtures. What is more, the free-air radar operates has no contact with the medium, which means that material resistance is less of an issue.

VEGA uses high-quality materials like 316L stainless steel and, for radar antennas, the super tough plastic PEEK, which guarantees a long service life and maximum chemical resistance, even in extremely aggressive media. These properties are indispensable in chemical logistics, where reliability is paramount.

Measurement technology as a success factor for up-to-date, sustainable chemical logistics

In the Scharr project, plant engineering firm Göhler implemented very high safety standards and used additional mechanical level switches to minimise risks.

“VEGA measurement technology sets standards in operational safety and measurement accuracy for these processes,” explains René Kozica, project manager at Göhler.

The project impressively demonstrates how technological innovations solve big challenges in chemical logistics – while meeting legal requirements and high safety standards as well as offering economic benefits, especially in the form of operational efficiency. Measurement technology is thus far more than just a technical component – it is the key to sustainable storage of hazardous substances. By making use of diverse redundancy – i.e., combining different measuring principles – Scharr achieves the highest level of operational safety. Even though modern radar systems can already take over the task of overfill prevention in compliance with WHG (German Water Resources Act), Göhler relies on additional mechanical point level sensors to minimise risks.

Related industries

Chemical industry

Products

Related posts

How measurement technology is advancing sustainability in the chemical industry

Read more

Chemicals distribution 4.0 – Digital transparency through VEGA sensors and VEGA Inventory System

Read more

Reliable instruments for challenging applications – How measurement technology secures the chemical industry

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}