Preventing overflows in fly ash silos: Application of the Month

Fly ash, also known as coal ash, is one of the byproducts of coal burning power plants. Power plants in the United States alone produce over 110 million tons of fly ash every year. All of this can be hazardous to the environment, polluting waterways, groundwater, drinking water, and the air. That’s why governments around the world, including the United States’ Environmental Protection Agency, regulate this material and hand out hefty fines if it’s not collected and then disposed of properly.

Power plants typically collect fly ash with electrostatic precipitators or other types of filters and then store it in silos before hauling it away to dispose of it or sell it for reuse. The amount of fly ash in each silo needs to be closely monitored to avoid overflows, which result in safety hazards, partial shutdowns, additional cleanup costs, and substantial fines from the EPA. However, accurately and reliably measuring the level of fly ash inside the silo is a challenge.

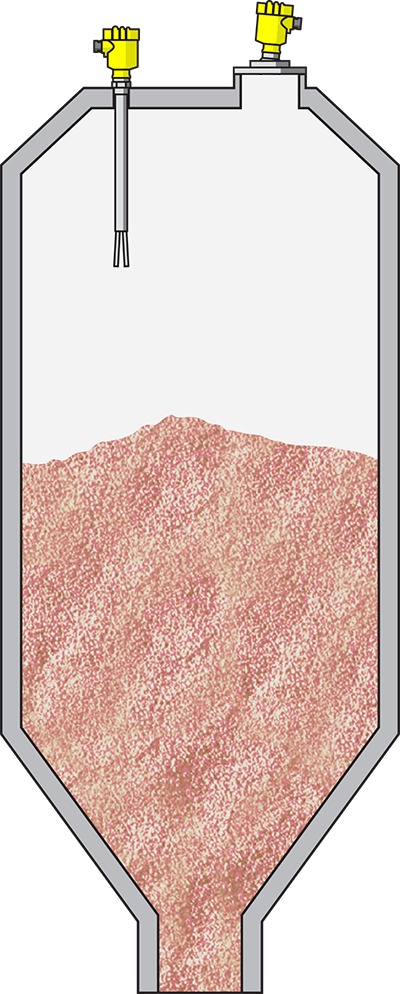

At first glance, the fly ash silo looks like any other bulk solids silo. They’re typically tall metal cylinders with a conical hopper at the bottom, so a truck can easily pull in and haul the ash away. Inside these silos, it’s an extremely dusty environment with very fine particulates hanging in the air. During filling, the dust is even worse, and it can be noisy. Both of these factors make it difficult to nearly impossible for ultrasonic or lasers to reliably provide an accurate measurement.

At a glance:

Fly ash silo, ash bunker

Level measurement and point level detection in the fly ash silo or bunker

The burning of coal creates huge quantities of ash. It is collected in a silo or bunker and then dumped into an open pit. To determine the filling height, radar transmitters and level detectors are deployed in the respective vessels.

Reliable

Reliable content measurement in the fly ash silo

Cost effective

Maintenance-free operation through non-contact measurement

User friendly

Simple mounting and setup

A non-contact level measurement solution

The VEGAPULS 69 is an 80 GHz radar sensor specifically designed for bulk solids and fine powders like fly ash. This radar is able to read through the dust and buildup because its signal can ignore the particulates in the air. Plus, radar signals are immune to any additional noises. This means the radar signal can move through the dust-filled air and still hit the surface of the product in the silo to provide an accurate and reliable level measurement every time. The 80 GHz frequency gives the radar a narrow beam angle, allowing it to focus most of its energy onto a singular, small spot, like the bottom of the cone of the silo. The spot on measurement gives operators peace of mind knowing they’ll avoid any overflows resulting in costly clean-ups and EPA fines.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}