Storage tanks for acids

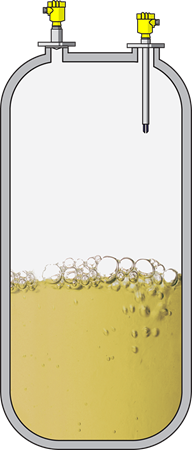

Level measurement and point level detection in storage tanks for acids

Process data

Measuring task:

Level measurement and point level detection

Measuring point:

Tank

Measuring range up to:

4 m

Medium:

Sulphuric or hydrochloric acid

Process temperature:

-40 … +50 °C

Process pressure:

0 … 0 bar

Special challenges:

Aggressive media

Application

The raw water, which is usually extracted from a river, cannot be fed untreated directly into the turbine circuit of the plant. It has to be treated first. To neutralize the water, either sodium hydroxide (NaOH) or hydrochloric acid (HCl) is added. Level sensors supply the measurement data required to ensure a high availability of these chemicals and others used to treat the feed water.

Your benefit

Reliable

High operational reliability through the use of chemically resistant materials

Cost effective

Yearly WHG test can be carried out by pressing a button

User friendly

Reliable, maintenance-free measurement

Recommended products

VEGAPULS 6X

The non-contact radar sensors are optimized for reliable measurement of aggressive media

- High acid resistance through optimized antenna design

- Reliable technology ensures high measurement certainty

- Very high operational reliability and long service life thanks to non-contact measuring method

Measuring range - Distance

120 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

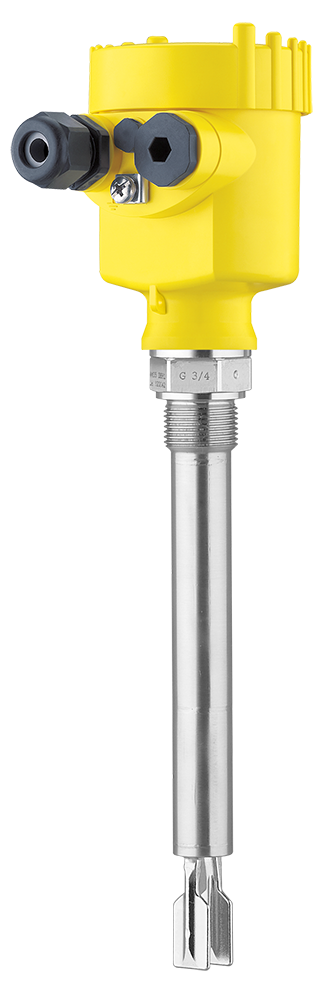

VEGASWING 63

The universally applicable vibrating level switch reliably prevents an overfilling of the container

- Product-independent switching point ensures millimetre-exact detection of the limit level

- Minimal costs for maintenance and servicing

- Available in different materials, includes Ex, WHG and SIL2 approvals

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Close