Gas storage tank

Volume and pressure monitoring in a gas storage tank

Process data

Measuring task:

Level and pressure measurement

Measuring point:

Container/pipeline

Measuring range up to:

0 … 30 m

Medium:

Gas

Process temperature:

0 … +50 °C

Process pressure:

0 … +10 bar

Special challenges:

Chemical resistance

Application

The hydrogen produced in the electrolyser is temporarily stored in a gas storage tank. Depending on the design of the gas storage tank, either a flexible diaphragm of plastic or a floating roof is used for volume equalization. The gas volume and gas pressure are measured continuously to ensure reliable and safe operation.

Your benefit

Reliable

High measuring certainty without mechanical wear

Cost effective

Optimal information on the quantity of available gas

User friendly

Maintenance-free, reliable operation of the system

Recommended products

VEGAPULS 6X

Continuous level measurement with radar for permanent gas volume measurement

- Maintenance-free operation using 80 GHz non-contact radar technology

- Exact measuring results, independent of medium, process and operating conditions

- Simple integration into existing gas storage tanks

- Wireless operation via Bluetooth with smartphone, tablet or PC

Measuring range - Distance

120 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

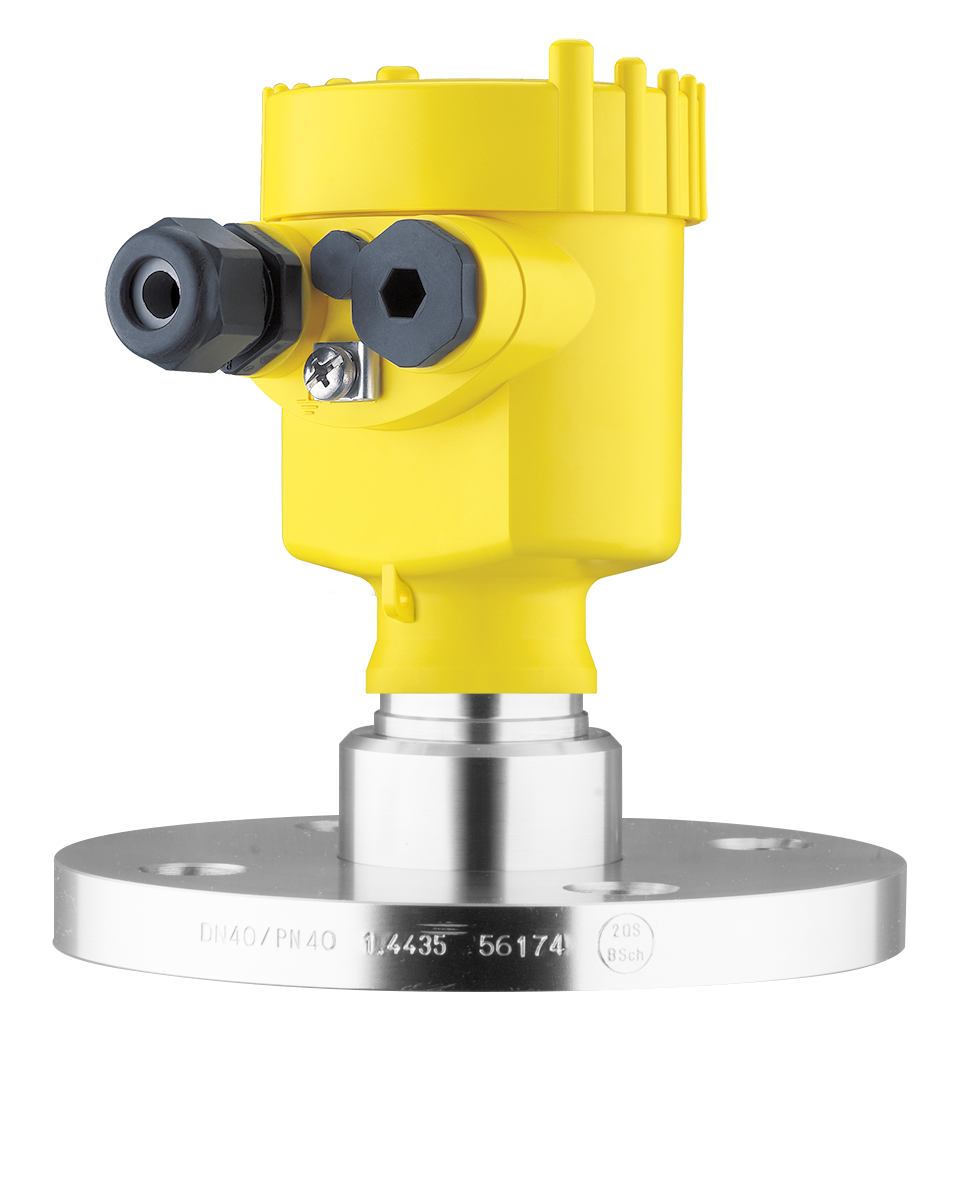

VEGABAR 82

Monitoring of the gas pressure in the gas reservoir

- High measuring accuracy through use of finely graduated measuring cells and measuring ranges

- Robust sensor construction for high availability

- Long-term stability of the ceramic measuring cell for maintenance-free operation

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 100 bar

Process temperature

-40 ... 150 °C

VEGATRENN 141

Separator (supply isolator) for optimal power supply to connected sensors

- On-site diagnostics for immediate status display via LEDs

- Simple parameterisation interface via HART sockets for convenient operation

- Guarantees galvanic isolation between sensor and PLC

Protection rating

IP20

Input

1 x 4 … 20 mA/HART sensor input

Output

1 x 4 … 20 mA

Close