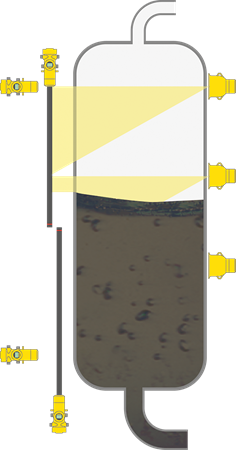

Coke drums

Density, level measurement and point level detection in coke drums

Process data

Application

Your benefit

Recommended products

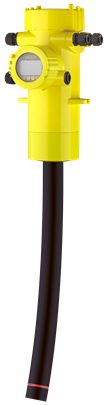

FIBERTRAC 31

Radiation-based sensor for continuous level measurement in coke drums

- Lightweight construction eliminates need for cranes or special rigging for mounting

- Long detector length minimizes the need for additional platform construction

- RS485 gauge to gauge communication network offers extensive diagnostics and reduced troubleshooting time

MINITRAC 31

Radiation-based density and point level measurement in coke drums

- Non-contact measurement unaffected by fluid viscosity, deflection or refractive properties

- Monitors anti-foam injection effectiveness

- RS485 gauge to gauge communication network offers extensive diagnostics and reduced troubleshooting time

- Re-zeroing of the system with each cycle improves accuracy

VEGASOURCE 83

The source holder is used to hold and secure the radioactive source

- Small footprint and simple installation

- Operational reliability through pneumatic opening and closing of the source container

- Trustworthy shielding allows use without control area

Close