Efficient against fish lice

Aquaculture operators combat the spread of fish lice, either chemically or mechanically. So-called “lice tubes” are increasingly being used. When the fish swim through these tubes, the lice are mechanically sucked off their bodies using a negative pressure.

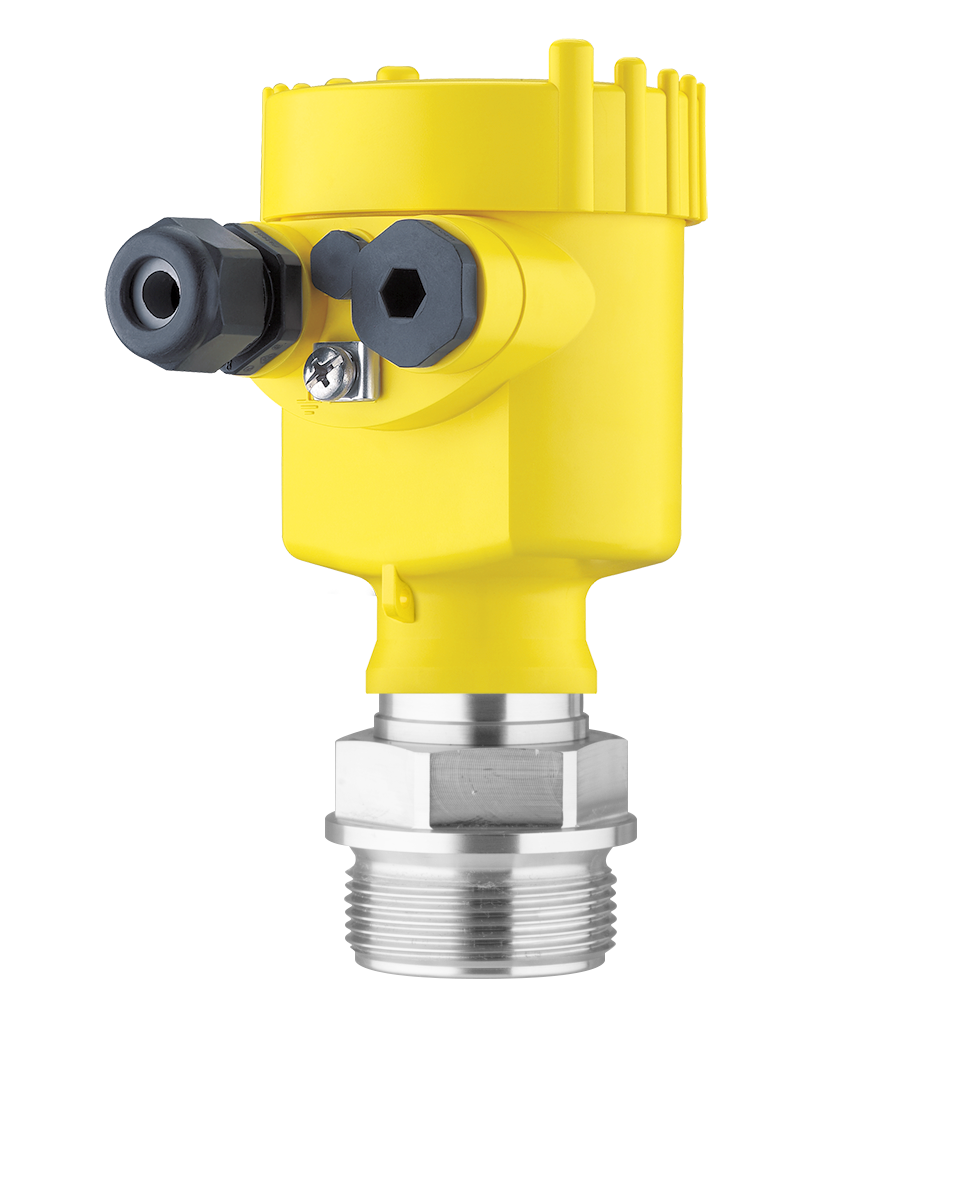

VEGA pressure transmitters ensure the correct process conditions and, thanks to their front-flush ceramic process fittings, avoid possible injuries to the sensitive animals.

To the application

For liquids

For bulk solids

Capacitive level switches

Vibrating level switches

Process pressure measurement

Hydrostatic pressure measurement

Am Hohenstein 113

77761 Schiltach

Germany

Tel.: +49 7836 50-0

Fax: +49 7836 50-201

info.de@vega.com

www.vega.com

Callback service

Ask for one of our experts to call you back.

Request a return callIn urgent service cases, please contact us directly via our 24-hour service hotline.

Close