VEGA Pressure Measurement Technology for the Production of Decor Paper

The Felix Schoeller Group develops, produces, and markets specialty papers for photographic applications, digital printing systems, and for the furniture and wallpaper industries, among others. The company rose up from humble beginnings to become the world market leader in photographic and decorative papers.

The group’s corporate philosophy, "Best Performing Papers Worldwide," implies the highest standards of quality and flexibility in paper production, and this applies to every plant component – including the deployed measurement and automation technology.

Decor papers are special papers for the surface finishing of wood-based materials for furniture, floors, or wall panels. The optical quality of the end product is of the utmost importance, so very high demands are placed on their creation. In decor paper production, sensors are particularly vulnerable to wear and tear due to abrasive fillers like titanium dioxide and in-line, high-pressure cleaning of the pipelines.

For pressure transmitters, this often results in high failure rates and a service life of only a few weeks. Every time a sensor is replaced, it involves a costly pre-calibration of the instrument in the installation position in the workshop and frequent recalibration after installation. To avoid this, maintenance planners decided very early on to use pressure transmitters with ceramic measuring cells from VEGA.

Since then, VEGA’s precise, overload-resistant pressure transmitters have been ensuring the integrity of all decisive production steps on PM 15 – from the dye mixing system to the headbox, and from the dryer section to the calendar.

Unique features of VEGA pressure transmitters with ceramic measuring cells

Color hue is one of the most important parameters in decor paper production. On PM 15, it is adjusted with four dye-metering stations integrated in the online coloring process.

It was previously only possible to dose the required amount of water for one dye batch at a time via a common flow measuring system. Since the installation of high-precision VEGABAR 82 pressure transmitters, water is added via level control through simple on/off valves at all 4 stations simultaneously.

Having exact information on the quantity remaining in the pigment batch container now makes it possible to prepare the next batch with a changed concentration and avoid discarding the residual liquid. This has resulted in a substantial savings of raw materials.

In the past, the pressure transmitters with metallic diaphragms were often damaged when the process vessels were being cleaned. Sensors with ceramic measuring cells have a clear advantage here, because they are far more robust. The conversion to VEGABAR 82 sensors has resulted in the reduction of travel times, an increase in capacity, color pigment savings, and improved quality and process continuity.

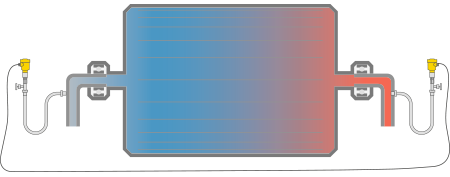

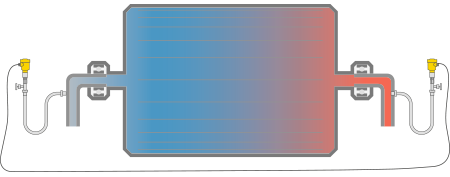

At the headbox, a fiber suspension is sprayed onto the wire screen. The jet velocity of this suspension determines the strength of the paper in both the lengthwise and crosswise direction. It should be identical to the wire speed, but with small intentional variations, operators can set the longitudinal/transverse ratio.

The VEGABAR 82 flush-mounted pressure transmitters installed at the headbox on the operator side and drive side allow the dynamic pressure to be precisely measured. Possible pressure differences between the two sides are detected and can be compensated by the return flow of the cross-flow distributor.

This is where the special features of this pressure transmitter come into play: very high measurement accuracy (measuring error < 0.05%), absolutely flush installation in the side wall of the headbox, and a space-saving design in protection class IP 68 (25 bar).

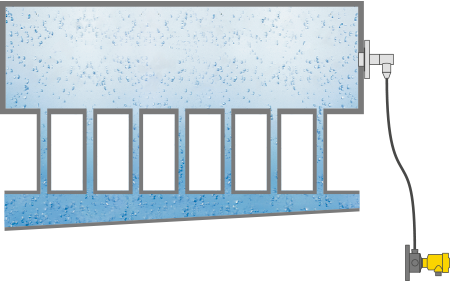

If the differential pressure is too high, the wall of the drying cylinder may be washed out, and if the differential pressure is too low, drying cylinders may "drown." Either can result in speed fluctuations, sudden speed drops, breakage of the paper web, and even production downtime.

Since the installation of VEGABAR 82 sensors, only the pressures on the inlet and outlet sides of the dryer groups are measured. The high accuracy of the transmitters enables calculation of the differential pressure in the mbar range (with measuring ranges up to 15 bar) and thus continuous, uninterrupted production.

Summary

Related applications

Drying-cylinder

Differential pressure measurement in the drying cylinder

To the applicationHeadbox

Pressure measurement in the headbox

To the applicationDrying-cylinder

Differential pressure measurement in the drying cylinder

To the applicationWe need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}