Clean and smooth dairy storage operations with VEGABAR 82

A major dairy processing plant in Amarillo, TX, is responsible for packaging, processing, and storing dairy and non-dairy products for human consumption. Since 1934, their operations have expanded across a facility the size of a city block with over twenty external tanks and many more internal vessels. As a producer of milk, cream, cottage cheese, dips, juices, tea, water and more, having reliable and accurate pressure measurements are essential for hygienic and quality standards to be met. While their current pressure sensors were initially accurate, with repeated exposure to their clean-in-place (CIP) systems, the sensors would wear out and start to give inaccurate measurements.

Cleaning comes with a cost

A competitor’s devices, used to measure the level of milk in their storage tanks, gave accurate measurements in the beginning, but would soon prove to be a maintenance issue for plant operators. The metal diaphragm measuring cells couldn’t hold up to temperature fluctuations and the relatively aggressive CIP process. Over time, the sensors would wear out and cause inaccurate readings, necessitating repeated replacements.

Plant operators had to perform shutdowns whenever a sensor went bad, and when they had to order a new sensor, long lead times and high prices cost the team valuable time and money. Ultimately, repeated shutdowns and maintenance costs prevented the team from making sure their quality and hygienic standards were met. They needed to find a better way to operate.

Holy cow! A new, reliable pressure device

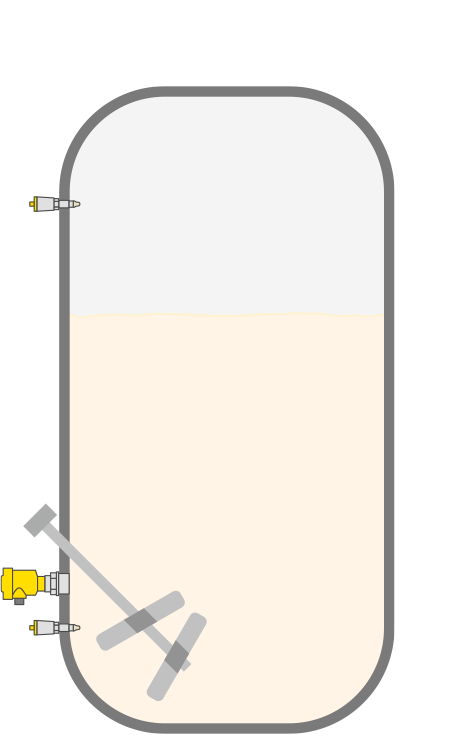

After experiencing repeated failures with their previous pressure sensors, plant operators spoke with VEGA about solving their current problem. Prior success with VEGA instrumentation kickstarted the conversation, and with VEGA as their trusted advisor, a plan was devised to run a trial of a VEGABAR 82 with a ceramic measuring cell on their milk storage tanks. The durable ceramic measuring cell is not affected by temperature fluctuations and harsh cleaning process conditions, and the sensors are easy to commission and troubleshoot.

A VEGABAR 82 was installed where a competitor’s device had recently failed, and with a successful trial the plant is now replacing competitor sensors as they wear out. The team was immediately impressed with the new sensor’s durable measuring cell, and the superior support offered by VEGA’s field service team gave them a renewed peace of mind for any questions or concerns they have. With easy setup and commissioning, replacing old, faulty competitor sensors is a breeze, minimizing their downtime and increasing their throughput.

The VEGA Difference for dairy pressure measurement

Process efficiency has increased since switching to the VEGABAR 82. Reliable and precise pressure transmitter measurements mean less maintenance and more money put back into their pockets, allowing the plant to focus on better ways to use the resources they have at their disposal. Plant operators can check statuses remotely via Bluetooth connectivity and the VEGA Tools app, and with the VEGA support team by their side day and night, any question or concern that comes up can be resolved quickly. With a brand new, durable pressure sensor solution at their disposal, the dairy team now has a sensor they can “set and forget” instead of constantly wondering if their measurements are accurate or how long it will last before maintenance is required.

Dairy processing plants need accurate and reliable measurements they can count on day in and day out. Better inventory tracking, less down time, improved efficiency, and better service are all things plants look for when optimizing their business. That’s why this plant chose the VEGABAR 82 and other VEGA measurement solutions.

Related industries

Dairy

To the industryRelated applications

Storage tank for milk and milk products

Level measurement and point level detection in the storage tank for milk and milk products

Milk and milk-based products such as cream, standard and pasteurized milk have to be stored in the correct quantities depending on production requirements. Since whole milk tends to separate into milk and cream even at low temperatures, it has to be circulated during storage. The quality of the milk must not be affected by stirring. To ensure that the circulation does not begin until the agitator is completely covered with product, a reliable measurement is required.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Certified hygienic design of the sensors reduces cleaning time

User friendly

Very simple sensor installation

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}