Limestone quarry – Mass flow measurement on a conveyor belt

Application

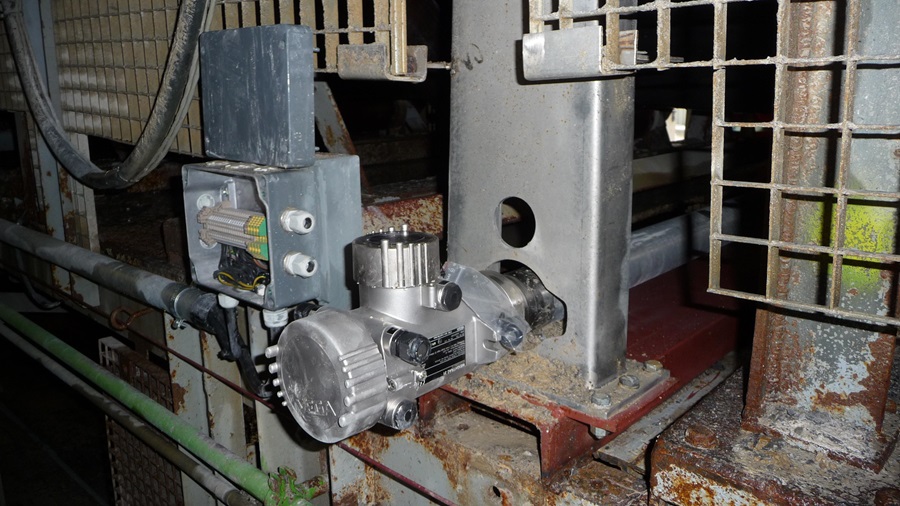

The solution

To regulate the primary crusher, the operator needs accurate, and above all reliable, mass flow measurement. Strong vibration, dirt, noise, moisture and dust make the measurement extremely difficult. The company had been using a mechanical belt scale to measure the flow rate. But the rough ambient conditions often falsified the measured values. The radiation-based measuring system WEIGHTRAC measures the mass flow on the conveyor belt continuously and contactlessly. The required belt speed is determined by the process control system. To ensure uniform throughput, the measurement data from WEIGHTRAC is used to control the output of the primary crusher. The detected material quantities can also be summed in the process control system. WEIGHTRAC is maintenance free and can be easily mounted on existing conveyor belts The robust and reliable measuring system ensures smooth operation in the downstream production processes and makes it possible to optimize plant efficiency.

User benefits

- Optimization of transport capacity through precise flow measurement

- Maintenance free thanks to non-contact measuring principle

- Unaffected by environmental influences - reliable quantity measurement

- Long service life thanks to robust measuring system

- Simple installation on existing conveyors