Effective level control in milk of lime mixing vessel

As the sole processor of the UK’s beet sugar crop, British Sugar work in partnership with 3,500 growers and customers to deliver a world-class product that is made to the highest standards every day. Processing around eight million tonnes of sugar beet and producing up to 1.4 million tonnes of sugar each year, they are the leading producer for the British and Irish food and beverage markets.

Sugar beet processing is a complex and demanding process. To consistently produce the highest quality product and maintain the lead in efficiency, the organization requires continuous innovation and process enhancements. One recent improvement at its Newark production site is the production and mixing of milk of lime. This is an essential formulation for use in sugar production when purifying the juice from beet or cane.

Typically, 125 kilograms of limestone is used in the production of one ton of sugar, so it is a significant process input. Sugar beet is sliced up and passed through a diffuser to extract the sugar juice. Lime, produced from calcium limestone, is used in the next stage of the production process. It is converted into milk of lime and this is used to capture and remove impurities in the juice of sugar beet. A high quality lime-water mixture is required in the sugar process to ensure an efficient, high quality sugar juice purification stage.

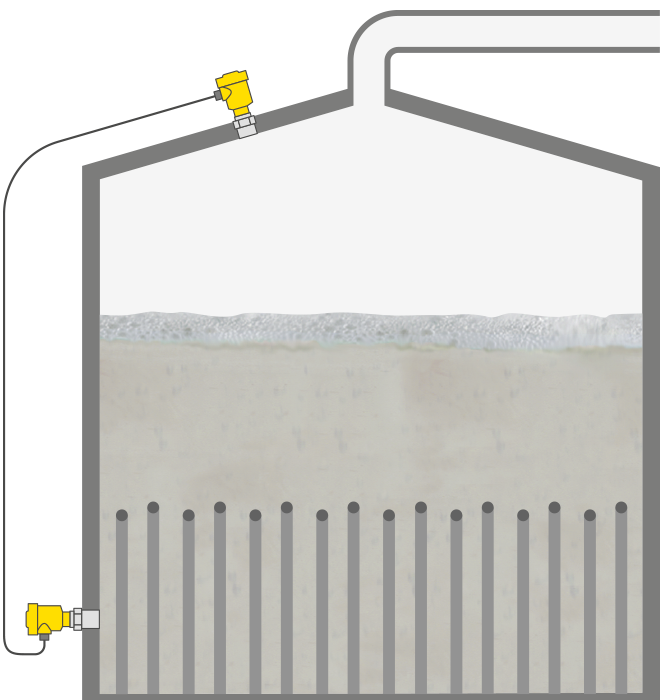

Most sugar-processing plants have their own lime kilns, and they require good, high purity limestone to burn. This ‘high calcium’ limestone is converted into quicklime in lime kilns, at a temperature of 900°C. To obtain milk of lime, the ‘calcined’ lime is mixed with water, and it is during this process an accurate, reliable level measurement ensures consistent production.

Reduction of operating costs and maintenance effort

A differential pressure transmitter with a modified back-pressure bubbler system was originally used to try to maintain a clear level measurement. However, maintenance was unpleasant and running costs were still high due to the use of compressed air. Accuracy was constantly compromised by tube blockages, build up, and of course, from the changing density as the lime was added into the water. On top of all this, the exothermic reaction of mixing the alkali and water produces heavy condensation inside the tank.

The process area requires a necessary high level of safety as the lime is harmful and an irritant to both the skin and the eyes. Tank overflows and any consequential clean-up are unpleasant and hazardous. Any form of level control that can increase reliability and reduce exposure of maintenance personnel in this area of the plant is essential, and British Sugar was keen to look for a new measurement solution.

Buildup and difficult installation position are no problem with the high measurement frequency of 80 GHz

Finding the ideal mounting position proved to be another challenge. To minimise splashing and build up on the sensor, it needed to be situated quite close to the vessel wall – not an ideal position for a contactless level sensor. The proximity of the wall and any build up can interfere and compromise both performance and accuracy. The VEGAPULS 64, however, uses 80 GHz frequency, which means its DN80/3” flange only has a 3 degree beam angle. The result: the radar sensor handles the situation with ease. A more focused sensor signal beam bypasses the vessel wall and any build up, following the level confidently.

VEGA 80 GHz radar possesses some unique performance characteristics, like an unrivaled sensitivity, using a dynamic range of 120dB. Combining the sensitivity with the enhanced focusing and market-leading signal processing software creates a formidable package. These abilities enable it to overcome challenges like mounting close to vessel edges or through valves and long nozzles and aimed at a turbulent or agitated process surface. This radar sensor can even make a reliable measurement when heavy condensation and build-up are on the sensor face. This application just happened to deal with all of these at once.

British Sugar at Newark are very happy with the results from this application. An improved, reliable level measurement ensures better quality milk of lime and less maintenance time lost working on instruments or clean ups in their lime mixing plant.

Food industry

Related applications

Sugar vacuum pan

Level measurement in a sugar vacuum pan

The process in a vacuum pan is designed to ensure the growth of sugar crystals. The syrup is cooked in a closed boiler with steam-heated tubes and the liquid is extracted. The intermediate product is magma, a mixture of crystal sugar and syrup. This mixture is then poured into a holding tank, the crystallizer. In the holding tank, the cooling and drying process creates a substance called massecuite, from which the sugar crystallizes. The level in the tank must remain constant, so a reliable level measurement is required here.

Reliable

Approved materials according to EC 1935/2004 and FDA

Cost effective

Sensors exhibit high, long-term stability

User friendly

Simple installation and setup

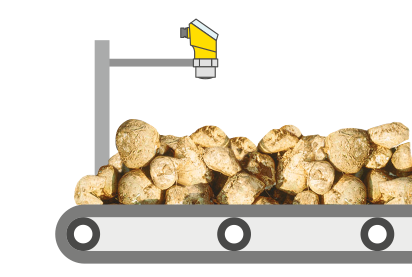

Conveyor belt for sugar beet

Measuring the level of sugar beets on the conveyor belt

The delivered sugar beets are poured from trucks onto conveyor belts that transfer it to the washing and shredding facility. Multiple level sensors are required to monitor the loading of the beet as it goes on the conveyor belt to optimise the feed rate and energy usage.

Reliable

Reliable monitoring of belt loading

Cost effective

Measurement enables optimal control of the flow rate

User friendly

Simple setup and maintenance-free operation

Sugar dissolver vessel

Level measurement in the sugar dissolver vessel

In beet sugar refining the raw sugar is heated and dissolved in water into liquor. There are typically several interconnected agitated vessels in this process, each one with a weir allowing the liquor to flow from vessel to vessel. During the dissolving process, sugar byproducts from the downstream refining process are reintroduced to enable sugars to be recovered. To ensure a continuous process, a reliable level measurement is required.

Reliable

Reliable measurement, unaffected by surface, foam and condensation

Cost effective

Maintenance-free operation

User friendly

Simple installation

Thickener for sugar beet juice

Level measurement in a thickener

The thin juice extracted from sugar beet is thickened by the reduction of excess water in multiple stages at the evaporator station. This evaporation process is carried out under vacuum and heat. The liquid in the evaporator boils so violently that great amounts of vapour are formed. A level sensor is needed to monitor and control the thickening process.

Reliable

Accurate, reliable measurement, even under adverse vacuum and condensation conditions

Cost effective

Reliable measured values allow efficient control of the evaporation process

User friendly

Narrow beam angle allows easier installation in vessel top

Related article:

VEGAPULS 64 provides reliability in the crystallization process in sugar production

Read moreRelated products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}