Fixing flow measurements with VEGADIF 85

An Ohio-based water treatment plant processes wastewater for over 86,000 residents. The Class A wastewater facility features several water intake tanks, distribution tanks, and three large storage tanks.

Residents rely on this plant to keep the water flowing and the community safe. For this plant to function properly, they need to accurately measure their flow rates via differential pressure. When flow readings are off, the entire process is put at risk. So, what happens when the measurements don’t line up with the flow charts?

The million-gallon difference

Like many wastewater treatment plants, this facility needs proper flow readings from venturi pipes into their treatment process. As water passes through a smaller opening, it creates a pressure drop. This drop, measured by a differential pressure sensor, is used to calculate the flow rate. Without accurate measurements, chemical dosing, energy usage, and labor are all put at risk. Too low treatments could lead to environmental violations and re-treatment, while too high would waste valuable chemicals and energy.

The plant’s original sensor was reporting flow discrepancies as much one million gallons per month between their measurements and the facility’s actual flow charts, increasing their operational costs and putting the environment at risk.

Finding an accurate differential pressure solution

When plant operators contacted VEGA, they wanted to turn their operations around. VEGA’s experts recommended a VEGADIF 85 with a valve block to be installed on their venturi pipe, which was then quickly installed and calibrated thanks to the sensor’s Bluetooth connectivity and the VEGA Tools app.

So, what stood out to the plant team? They appreciated the VEGADIF 85’s integrated overload diaphragm which offered much higher reliability than what the team was used to. Operators don’t have to worry about comparing pressure measurements against the facility’s actual flow chart values, reporting pinpoint accurate measurements with the new sensor. Troubleshooting the device can be done with ease, thanks to the Bluetooth connectivity and VEGA tools app, and personnel have access to VEGA’s support team for outside expertise and a personal touch for any future issues they might have.

The VEGA Difference for differential pressure measurements

The brand new VEGADIF 85 installation brought a slew of benefits to this wastewater processing facility. Accurate flow data gives operators the insights they need to fine-tune chemical dosing and reduce their overall energy consumption. They no longer worry about over treating or under treating their water, putting the environment and their budgets at risk. Long term, this plant can more accurately predict water usage without taking risks associated with the guesswork of their previous installation.

Wastewater plants rely on accurate flow rates to operate effectively. They have a responsibility to serve their communities well and continually improve their processes. That’s why this plant chose the VEGADIF 85 for their venturi pipe differential pressure measurements.

Related industries

Drinking water supply

Related applications

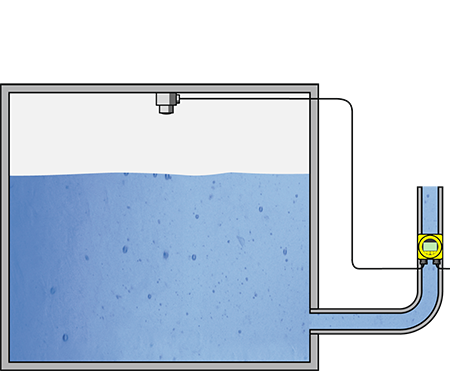

Pure water tank

Level measurement in the pure water tank

Pure water tanks are important storage facilities for periods of peak demand. They compensate for delivery fluctuations and enable efficient plant operation. The pure water tank is therefore not only a means of storage, it also serves as an equalizing tank. Reliable level measurement is therefore essential.

Reliable

High supply reliability because of dependable information

Cost effective

Maintenance-free operation

User friendly

Simple mounting and parameterisation

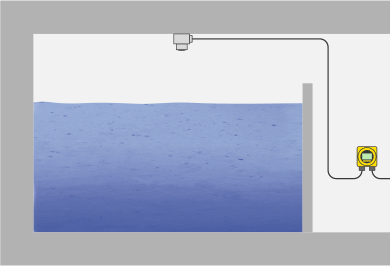

Elevated storage tanks

Level measurement in the elevated tank

Elevated water tanks are reservoirs located at high places that act as a buffer during periods of peak demand. They compensate for delivery fluctuations and enable efficient plant operation. Reliable level measurement is therefore indispensable.

Reliable

High supply reliability through dependable measurement

Cost effective

Maintenance-free operation

User friendly

Simple mounting and parameterization

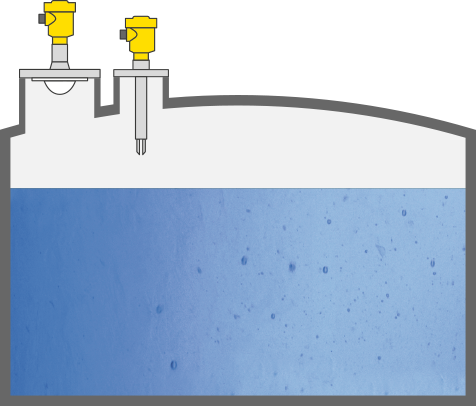

Water storage tanks

Level and point level measurement in water storage tanks

Water storage tanks are especially important in times of peak demand. They compensate for delivery fluctuations and enable efficient plant operation. The water storage tanks are therefore not just storage tanks, they also serve as equalising tanks. Reliable level and point level measurement are thus indispensable here.

Reliable

High security of supply thanks to dependable measurement data

Cost effective

Maintenance-free operation

User friendly

Simple mounting and setup

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}