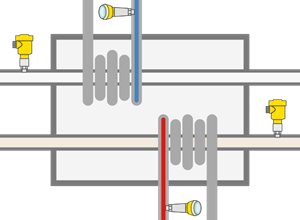

Heat exchanger

Pressure measurement during pasteurisation in the heat exchanger

Process data

Application

Your benefit

Recommended products

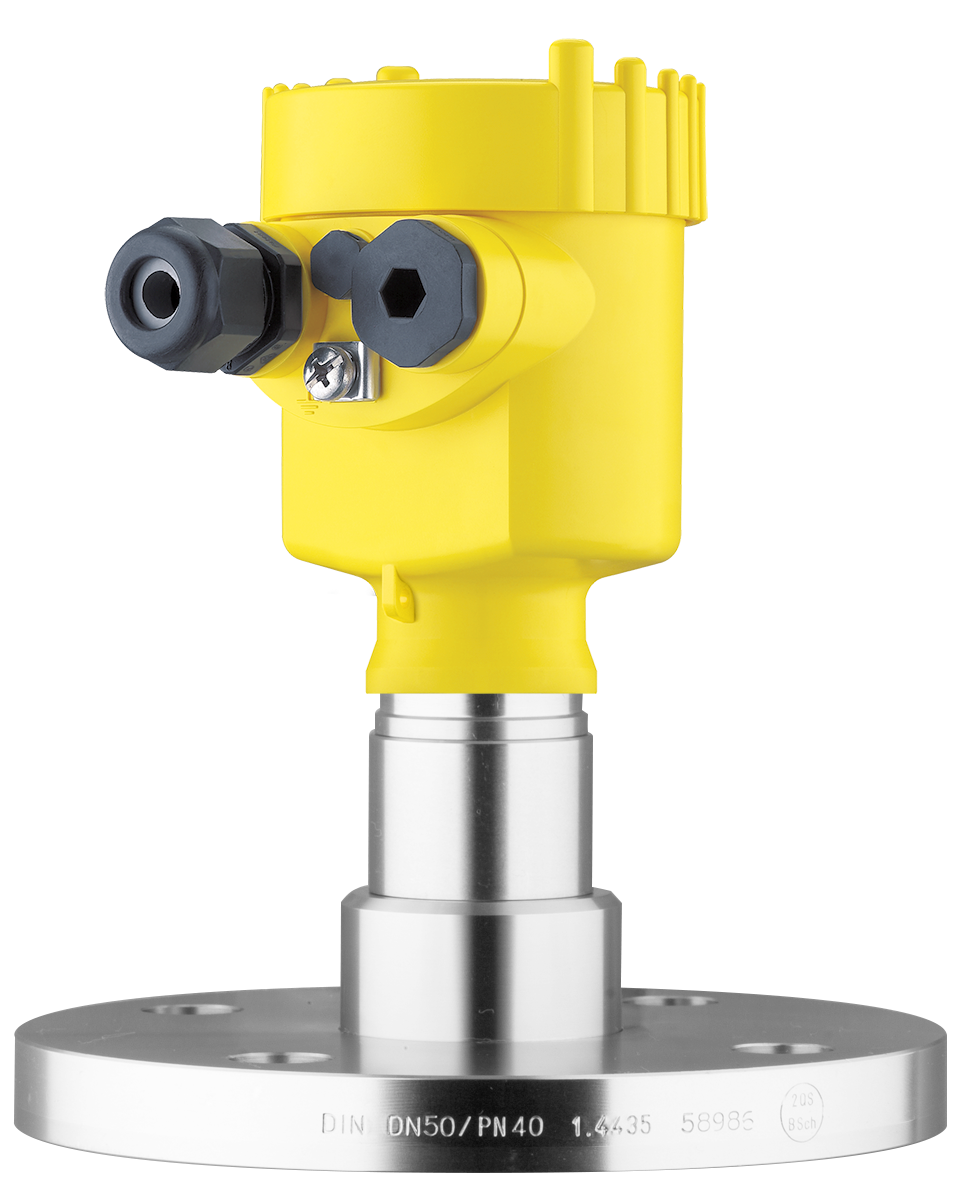

VEGABAR 83

Pressure transmitter for pressure monitoring in the raw milk and pasteurised milk pipelines

- Robust measuring cell guarantees long-term stability

- Suitable for CIP cleaning processes, temperature resistant up to +150 °C

- Bluetooth communication for easy diagnosis

VEGABAR 38

Pressure sensor with I/O link connection for pressure monitoring in the feed line for the cooling medium

- Simple operation thanks to VDMA menu structure and integrated display

- Ceramic CERTEC® measuring cell is totally resistant to cooling water

- Thanks to the 360° status display, the different operating statuses can be clearly recognised

VEGABAR 39

Pressure sensor with I/O-Link connection for pressure monitoring in the feed line for the heating medium.

- Reliable measurement thanks to fast response time

- Simple operation thanks to VDMA menu structure and integrated display

- Bluetooth communication for easy diagnosis

Close