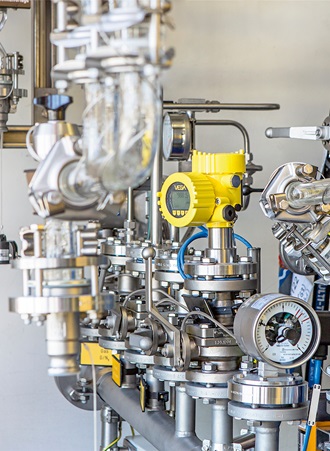

Pressure transmitter with ceramic CERTEC® measuring cell meets the stringent demands of the pharmaceutical industry

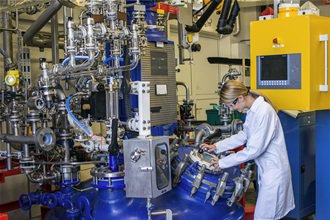

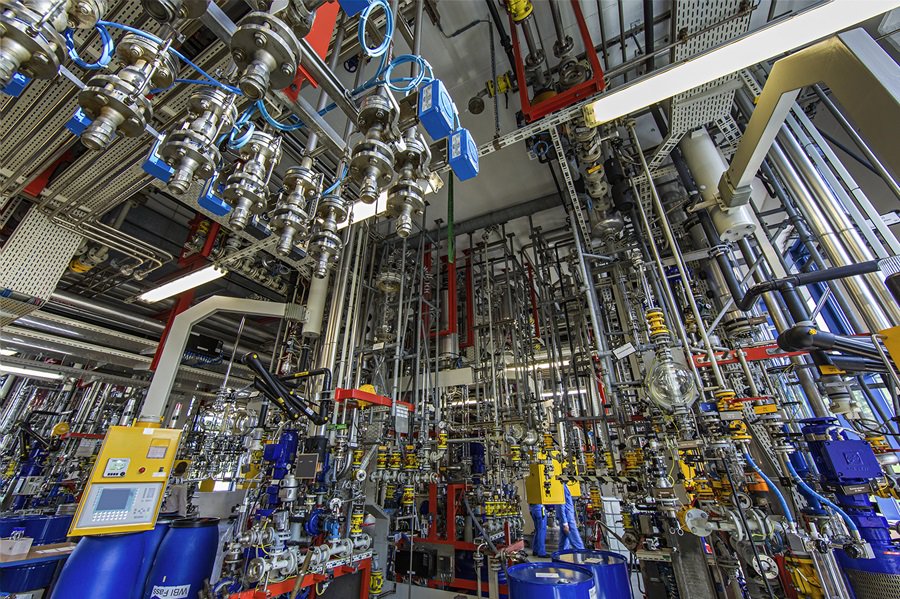

With headquarters in Bubendorf, a Swiss town of less than four and a half thousand inhabitants, CARBOGEN AMCIS AG is located right in the middle of the so-called Swiss Pharmaceutical Cluster. The company specializes in exclusive intermediate products for the big players in the industry. Here, VEGABAR 82 pressure transmitters greatly simplify things: in the production processes as well as their qualification.

Ensuring simplified qualification: CARBOGEN AMCIS AG uses mostly identical, standardized pressure transmitters.

Concentration changes of the reacting solutions take place in milliseconds in many pharmaceutical processes.

Anyone operating a pharmaceuticals plant today must take care not to fall by the wayside when it comes to standardization.

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Products

Industrial sectors

Pharmaceutical

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}