Measuring technique for flow rate measurement

Measuring technique for flow rate measurement

Briefly explained: What is flow measurement?

How are flow meters constructed?

A flow meter basically consists of two main components: a sensing element, which serves as a flow sensor, and a transducer, which converts and evaluates the measured values. The sensing element can gather qualitative or quantitative information on certain physical or chemical properties as well as the material composition of its environment. The transducer then converts this recorded information into appropriate values, which are then output as processable variables, usually in the form of electrical signals.

What measuring methods does VEGA use for flow measurement?

What areas of application are there for flow measurement?

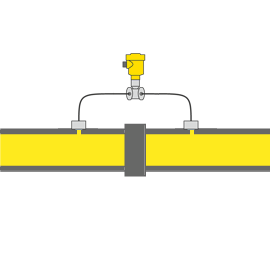

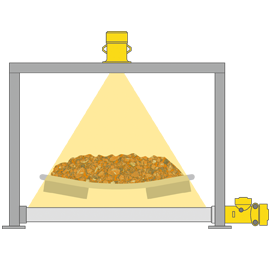

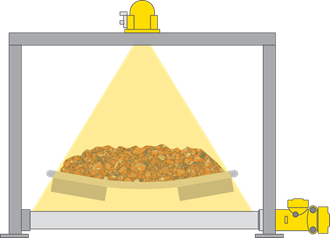

Mass flow determination on a conveyor belt

And, radiometry can also be used to measure mass flow in pipelines. In this case, too, a source holder with a slightly radioactive isotope emitting gamma rays is deployed, mounted on one side of the pipe. The sensor on the opposite side of the pipe measures the intensity of the incoming radiation. The higher the density of the conveyed liquid, the less radiation received. Together with an input from a flow meter, the output signal can be used to calculate the mass flow from the measured density. A typical example is the mass flow of abrasive materials such as slurries.

Application example for flow measurement

Close