VEGAFLEX 86 delivers precise measured values in crude oil processing

The desalinator contains high-voltage grids that accelerate the separation process of the phases. In the process, the saline water settles to the bottom, is drawn off downwards and fed to the appropriate treatment facilities. This is done at elevated temperatures of about 130 °C to reduce the viscosity of the crude oil. The desalinated crude oil is then pumped in the direction of the distillation facilities.

Coping with fluctuating densities

Until recently, a level gauging method that works according to the displacement principle was used at this measuring point. Besides the fluctuating density, other factors also affected measurement accuracy: vibration and turbulence. Nevertheless, this measuring system had been in use at the site for many years because there was simply no alternative. A classic interface measuring method just did not deliver the required accuracy. At one point the company tried using a TDR reference sensor from another manufacturer, but it did not work satisfactorily because its compensation range was not large enough.

A respected partner at two locations

A number of VEGA sensors are now in use at the Vohburg site, including many pressure sensors of the VEGABAR and VEGADIF series. VEGASWING 66, the universally applicable vibrating level switch, is also one of the VEGA instruments deployed there and has been particularly convincing in its performance. It is valued above all because of its very wide process temperature and process pressure range in the demanding refinery processes.

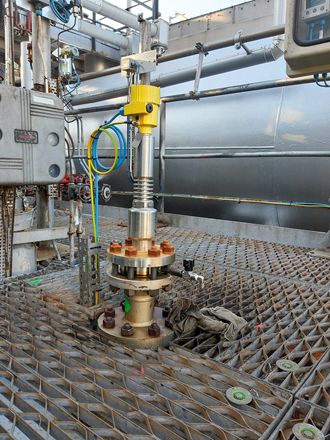

Bayernoil and VEGA worked together to develop a new solution for the problem of measurement in the desalinator. Two years ago, a measuring instrument based on guided radar, a VEGAFLEX 86 with a reference section, was installed parallel to the existing displacement solution. The purpose was to measure the interface between oil and water as accurately as possible, especially when the DK values of the crude oil fluctuate, making it possible to operate the system even closer to its limits.

Defying vibrations and shocks

In interface measurement with guided radar, the radar pulses are guided along a cable or rod probe and reflected by the product surface. The measuring probe of the TDR sensor ensures that the signal travels down to the product undisturbed. The series consists of four different instrument types, each of which is tailored to a particular application. VEGAFLEX 86 is often used for high temperatures and high pressure applications, e.g. in distillation columns or in crude oil processing. It has a ceramic insulation and graphite seal in the coupling that can withstand the penetration of steam at a maximum pressure of 400 bar and temperatures up to 450 °C. The spacers in the coaxial probe are also made of ceramic and mechanically stable enough to withstand the vibrations and shocks.

A good solution to the problem of fluctuating dielectric constants has also been developed for this sensor. This probe was originally designed to compensate for the signal propagation time in the steam atmosphere of steam boilers. A test should now provide answers as to whether this also works in the crude oil in a desalinator. Ultimately, the innovative steam compensation ensures higher measuring accuracy. The VEGAFLEX 86 used in Vohburg uses a reference section of 750 mm and has a probe length of 3,950 mm. Incidentally, the reference section for compensating for deviations is the longest one available on the market. The longer this distance, the more accurate the measurement.

Simple setup and commissioning

In order to improve the sensitivity of the sensor, a special signal processing algorithm was implemented in the development phase. It is based on false signal suppression during setup and commissioning. The sensor subtracts this false signal suppression from the visible echo curve. The result is a straight echo line.

The responsible technicians were eagerly awaiting the results of the practical test. As expected, the test ran smoothly. Commissioning was simple – the application was configured as a “normal” level measurement. Thus, no special settings were required to ensure a reliable measurement with sufficient measurement certainty.

Test run with a positive outcome

It quickly became apparent that the advantages of the self-compensating VEGAFLEX sensor had a positive effect on measurement accuracy, even with constantly changing crude oil quality. To be on the safe side, the displacement measurement was left in place so that the measured values could be compared with one another. The test run was consistently positive for 1.5 years, with no malfunctions during the entire period. After this successful test run, another desalinator with a VEGAFLEX 86 with reference section was put into operation last year.

Related industries

Oil and gas offshore

Refining and petrochemical

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}