Consistent chemical industry measurements with VEGABAR 82 electronic differential pressure

A medium-sized chemical manufacturer in Bishop, TX, produces different FDA-audited ibuprofen products. For over 25 years, this CGMP-certified plant has offered an ibuprofen portfolio consisting of four powder grades, a direct compressible grade, and two fast acting grades. The state-of-the-art plant has a completely closed system, requiring very little human intervention across over 100 vessels.

Due to the nature of their production site and the value of their product, consistent and accurate pressure measurements for their hexane bulk storage tank are essential for their systems to maintain quality and safety, manage inventory, and require little human intervention during the process. A traditional differential pressure sensor was already in place, but changing weather conditions negatively affected their measurements.

Measurements changing with the weather

Hexane is highly volatile and flammable. Without accurate measurements, any unexpected pressure variations could mean leaks, overfilling, or vacuum conditions, all of which could pose safety hazards if left unchecked. A competitor’s traditional differential pressure devices, installed to monitor levels of hexane in their bulk storage tank, were a decent solution until the weather changed. The capillary lines would experience measurement drift as the temperature outside changed from cold to hot and back again. As a result, plant operators experienced downtime for recalibration and ran into repeated production snags.

Related applications

Bulk storage tanks

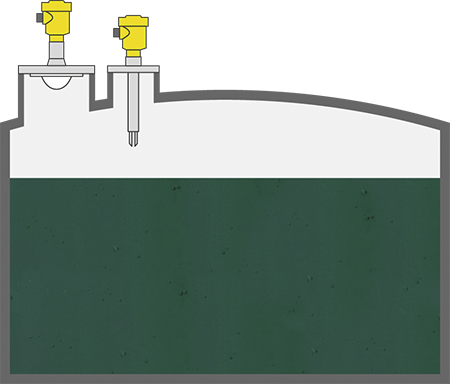

Level measurement and point level detection in bulk storage tanks

Dependable storage is not only the basis for reliable production and supply, it also protects against raw material shortages and price volatility. In addition to regulations on the use of overfill protection or safety instrumented systems, large storage tanks are also often subject to hazardous area codes of practice in conjunction with level measurement.

Reliable

Reliable protection against overfilling

Cost effective

Independent of product and process characteristics

User friendly

Simple setup and commissioning, maintenance-free

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}