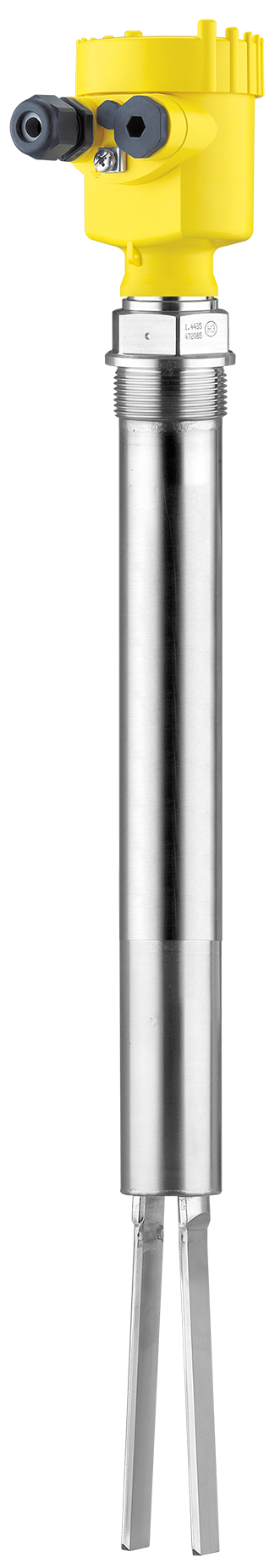

A simple, reliable point level vibration switch

The VEGAWAVE vibrating level switches reliably detect point level with exceptional accuracy directly at the mounting position. These can be used for high and low point level detection of powders, bulk solids, and even solids under water in any industry.

- Measures a wide range of products from fine powders to large rocks

- Robust, heavy-duty forks that last

- Easy installation and setup with no medium required

- FDA Approval for foodstuff applications

- Special configuration to detect solids under water

- Five electronic signal outputs available

Navigate this page:

VEGAWAVE 61 Compact Version

Process temperature: -50 ... 250 °C

Process pressure: -1 ... 25 bar

Version: standard, detection of solids in water, or with temperature adapter

Materials, wetted parts: 316L

Threaded connection: ≥ G1½, ≥ 1½ NPT

Flange connection: ≥ DN50, ≥ 2"

Hygenic fittings: Clamp ≥ 2", DN50 - DIN32676, ISO2852

Protection rating

- IP 66/IP 68 (0.2 bar)

- IP 66/IP 67

- IP 66/IP 68 (1 bar)

Output

- Relay (DPDT)

- Contactless electronic switch

- Transistor (NPN/PNP)

- Two-wire

- NAMUR

Ambient temperature: -40 ... 80 °C

Configure now VEGAWAVE 62 With cable extension

With cable extension

Process temperature: -40 ... 150 °C

Process pressure: -1 ... 6 bar

Version: Detection of solids in water or suspension cable

Materials, wetted parts: 316L, FEP, PUR

Threaded connection: ≥ G1½, ≥ 1½ NPT

Flange connection: ≥ DN50, ≥ 2"

Seal material: CR, CSM

Protection rating:

- IP 66/IP 68 (0.2 bar)

- IP 66/IP 67

- IP 66/IP 68 (1 bar)

Output

- Relay (DPDT)

- Contactless electronic switch

- Transistor (NPN/PNP)

- Two-wire

- NAMUR

Ambient temperature: -40 ... 80 °C

Configure nowVEGAWAVE 63

With tube extension

Process temperature: -50 ... 250 °C

Process pressure: -1 ... 25 bar

Version: Detection of solids in water, with tube extension, or with temperature adapter

Materials, wetted parts: 316L

Threaded connection: ≥ G1½, ≥ 1½ NPT

Flange connection: ≥ DN50, ≥ 2"

Hygienic fittings: Clamp ≥ 2", DN50 - DIN32676, ISO2852

Seal material: no media contact

Protection rating:

- IP 66/IP 68 (0.2 bar)

- IP 66/IP 67

- IP 66/IP 68 (1 bar)

Output

- Relay (DPDT)

- Contactless electronic switch

- Transistor (NPN/PNP)

- Two-wire

- NAMUR

Ambient temperature: -40 ... 80 °C

Configure nowCommon Industries

Food industry

Mining and metal production

Oil and gas offshore

Paper industry

Refining and petrochemical

Related applications

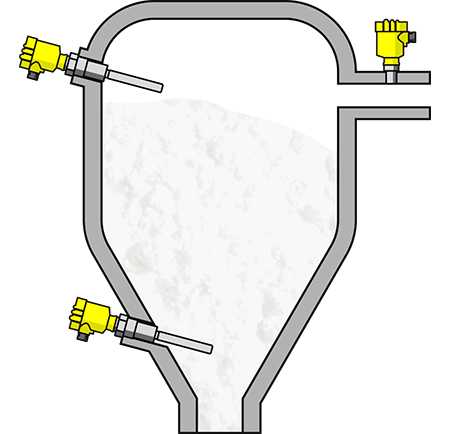

Buffer tank

Buffer tank pressure measurement and point level detection

In the smelter, above the fused salt electrolysis bath there are small buffer tanks that are pneumatically fed via pipelines. The alumina powder is dispensed into the melt bath in small quantities from these tanks. The filling of the buffer tank is controlled by the feed pressure. Full and empty alarms ensure optimal charging of the powder.

Reliable

Reliable function under all operating conditions

Cost effective

Simple installation into existing vessels

User friendly

Maintenance-free operation

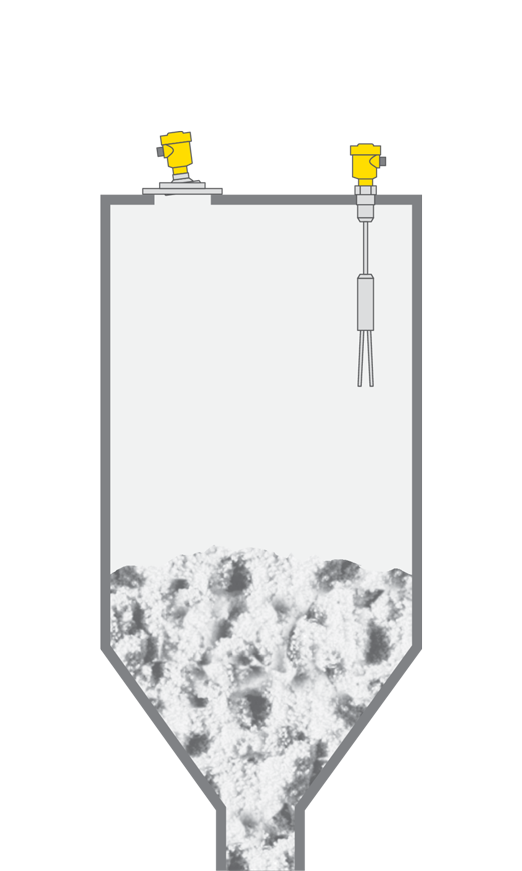

Lime powder silo

Level measurement and point level detection in lime powder silos

After the calcined lime is cooled, it is sorted into different sizes and stored for further processing. Most of the lime is further processed to lime powder. For optimum production planning, a reliable level measurement is a must.

Reliable

Reliable measurement ensured under all operating conditions

Cost effective

Optimal storage of the product

User friendly

Wear and maintenance-free

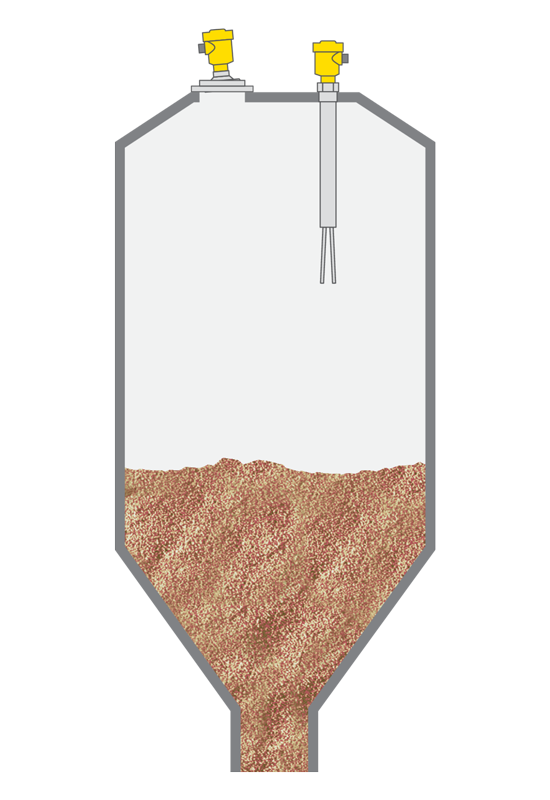

Raw meal silo

Level measurement and point level detection in raw meal silos

Before being burned in the rotary kiln, the material from the blending bed and the aggregates are ground to a fine raw meal in large mills. The powdery material is then transported to the silo by a pneumatic conveyor system. Reliable monitoring of the level is essential for optimal raw material storage.

Reliable

Reliable measurement ensures a continuous supply of raw material

Cost effective

Optimal stocks ensure continuous production

User friendly

Maintenance-free operation

Close