IIoT and the Future of Supply Chain Management

The Industrial Internet of Things (IIoT) is being heralded as the next big thing in industrial automation. Smart, imaginative industry professionals are devoting countless hours and energy to improving plant efficiency, personnel safety, and inventory management via IIoT. The excitement is palpable (A Google search of “IIoT” returns approximately 2.7M results) and deserved. IIoT brings together smart machines, sensors, advanced analytics, data storage, and people. This is truly an exciting time to be part of the automation industry.

At the tank level, IIoT technology has several benefits. Wireless connection from a sensor to a display via Bluetooth or a similar technology reduces material costs and installation effort when compared to traditional, wired instruments. This remote access allows users to make routine adjustments without climbing narrow ladders and walking scaffolds. In this way, IIoT is making plants safer for their people. As someone who spent years servicing products in the field and has found myself in some dicey situations, I am happy for the current generation of guys in the field. IIoT and remote sensor access means they won’t have to go through what I went through.

In other areas of the plant, IIoT allows for data collection from a network of level, pressure, and other interconnected sensors to a communication network via the cloud. This collected data gives users a look inside every process in the plant all at once without leaving their desks. Thanks to IIoT innovations, users can monitor and analyze processes, collect and share data, deliver valuable insights and make sound business decisions faster than ever before.

The advantages of IIoT in measurement sensors extend beyond inventory and production. The wealth of information and the ability for multiple parties to access it remotely is downright revolutionary as it concerns supply chain management. It sounds simple, but it’s true: You can’t manage what you can’t see. IIoT gives all stakeholders the power to see more than ever and that power is reaping enormous benefits. Reliable Trucking, a materials hauling outfit in California, is a prime example of how IIoT and remote access to real-time information can improve business practices.

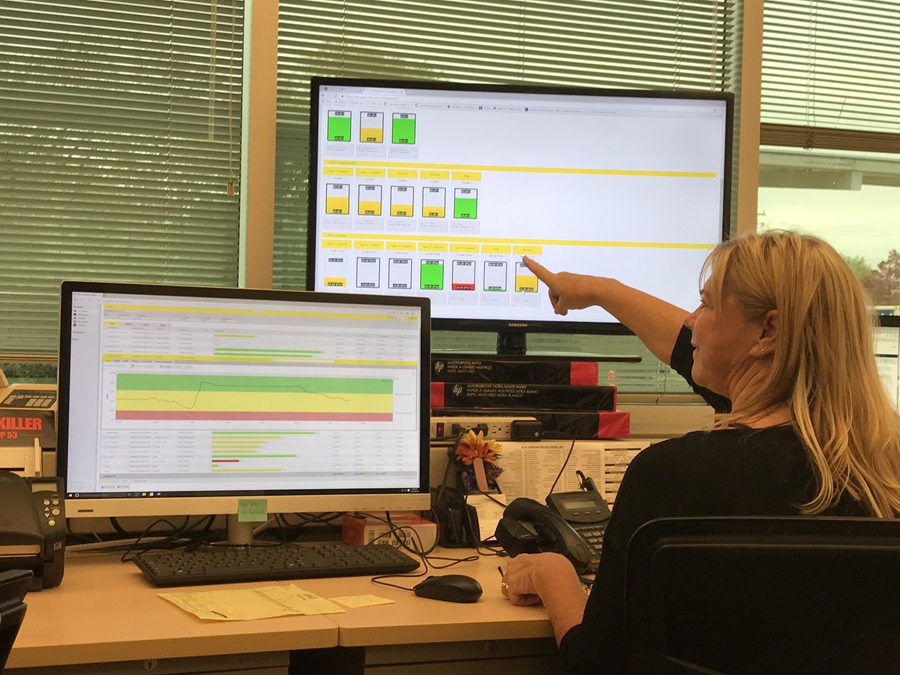

Reliable Trucking transports cement, fly ash, slag, and aggregates to ready-mix concrete plants in California. Ready-mix plants rely on Reliable Trucking to keep their silos sufficiently stocked in order to keep their production on schedule. All three stakeholders—the ready mix concrete plant, the hauling company, and the construction outfit—benefit from the VEGA Inventory System (VIS), a web-based software platform for remote inventory monitoring that pairs with VEGA through-air radar level sensors to deliver real-time information about inventory, consumption patterns, and free-space in storage silos.

Reliable Trucking and their ready-mix partners have remote access to silo level data. The hauling company’s dispatchers have become resources for production plants; they can keep an eye on site inventory and provide an accurate understanding of need while the ready-mix manufacturer focuses on their process. Responding to real-time inventory needs helps the ready-mix plant run more efficiently and safeguards against stock outs and situations where a truck arrives with a load and the site doesn’t have the space to store it.

Hauling companies also benefit from IIoT networks like the VIS. With a window into site inventory, dispatchers truck more intelligently than ever before. Gone are the days of trucks sitting at customer sites, waiting to unload. Optimized scheduling and routing are especially important for Reliable Trucking because they can avoid merciless traffic in San Francisco and other metropolitan areas around California. Using inventory data, dispatchers can schedule multiple truckloads to job sites early in the morning or late at night when highway congestion is at a minimum. The ready-mix plant produces efficiently, the construction site is always in stock, and the hauling company makes the most of its fleet. Everyone is happy and it’s all thanks to IIoT software and remote access to data.

The automation industry is just now scratching the surface of the Industrial Internet of Things. It’s an exciting time, full of possibilities and opportunities to improve our existing operations. By embracing new technology and improving access to information, all stakeholders benefit along the supply chain. Because you can’t manage what you can’t see.

Learn more about the VEGA inventory systemExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}