Ready-mix operations and materials haulers find a better way to do business

Managing what you can’t see

The largest hauler of dry bulk materials in North America delivers cementitious materials to ready-mix concrete producers across the country. This family owned trucking company ensures its customers have the material they need to keep their operation running. However, they found they were at the mercy of their customers’ demands, which weren’t always accurate.

Most ready-mix operations manually manage materials using perpetual inventory: logging incoming loads on a spreadsheet. Human error, unaccounted leaking gate valves, and other problems add up to inaccurate and untrusted measurements. As a result, operators order materials when they don’t necessarily need it, putting a strain on the trucking companies and causing inefficiencies in the supply chain.

Accurate measurements and information transparency

The trucking company saw room for improvement for everyone in the supply chain, so they worked with VEGA representatives to find a solution. That solution came in two parts: the VEGAPULS 6X and the VEGA Inventory System (VIS).

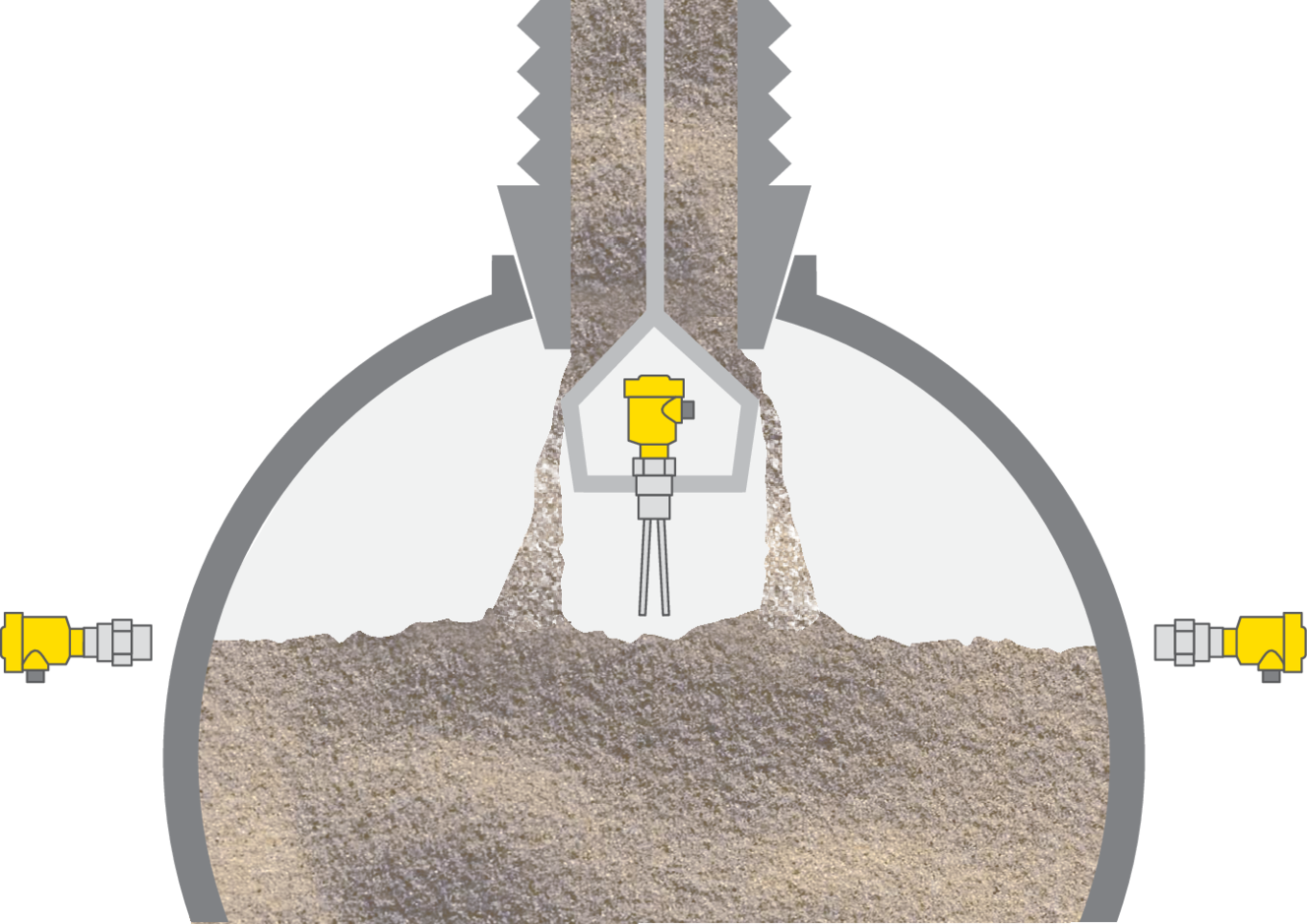

The VEGAPULS 6X is an 80 GHz radar sensor designed for measuring bulk solids. This non-contact level measurement can deliver an output to continuously track inventory. The sensor is ideal for aggregates and cementitious materials because the sensor has no moving parts and withstands dust, buildup, and noise.

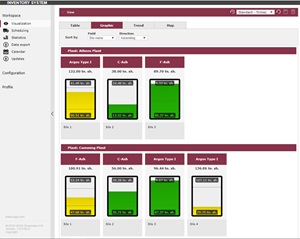

The VEGA Inventory System is a web-based software platform for remote inventory monitoring. Once paired with VEGA measurement sensors, it delivers real-time information about inventory, consumption patterns, and free space in storage silos. It does all this using an easy-to-understand color-coded configuration. Green means no need for a shipment. Yellow means the silo can handle at least one load. And red means the customer needs a shipment right away.

More efficient runs keep costs down

Once this IIoT solution was in place, everyone at the ready-mix plant and the trucking company was able to see reliable and accurate inventory for every silo at any time as long as they had an internet connection. This freed up the ready-mix company to focus on their own drivers and customers instead of worrying about replenishment plans. The trucking company could focus on making more efficient deliveries to better maintain their customers’ inventories. This two-pronged approach and working together secured the supply chain and added efficiencies that allowed both companies to improve their processes and keep costs low for their customers.

Once this IIoT solution was in place, everyone at the ready-mix plant and the trucking company was able to see reliable and accurate inventory for every silo at any time as long as they had an internet connection. This freed up the ready-mix company to focus on their own drivers and customers instead of worrying about replenishment plans. The trucking company could focus on making more efficient deliveries to better maintain their customers’ inventories. This two-pronged approach and working together secured the supply chain and added efficiencies that allowed both companies to improve their processes and keep costs low for their customers.

Related industries

Building materials

Related applications

Truck loading

Point level detection during the loading of trucks

Dust-free, closed loading systems are needed for fine aggregates and finished products such as cement. Automated loading of trucks is preferred in the industry and, while the load quantity is determined with a weighing system, it must be ensured that the truck is in the correct place and not overfilled. Reliable point level detection and vehicle positioning shortens loading times, increases throughput and improves the efficiency of the entire system.

Reliable

Reliable measurement under tough operating conditions

Cost effective

Optimal filling of silo vehicles

User friendly

Simple setup and commissioning

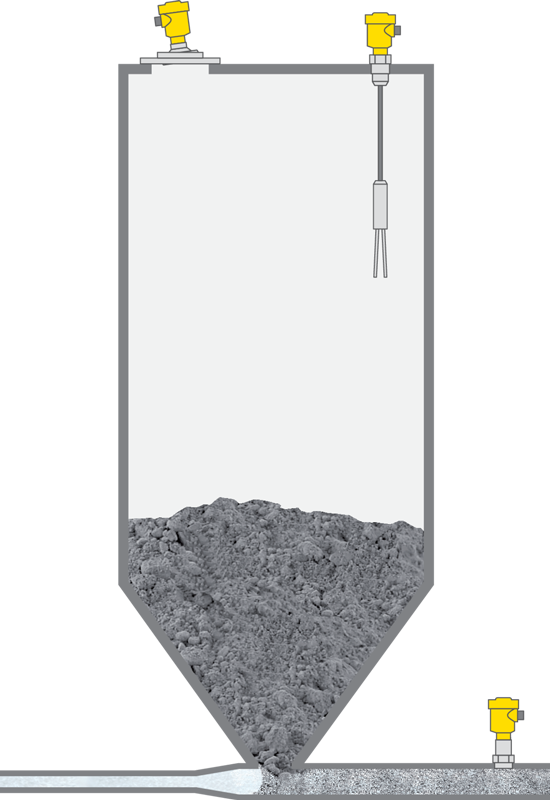

Cement silo

Level and pressure measurement and point level detection in cement silos

Before further processing, the cement is stored in tall silos. The cement is transported both in and out of the silo via pneumatic conveying. Efficient storage and transport of the product is ensured by accurate level measurement and point level detection, as well as also monitoring the pneumatic conveying system pressure.

Reliable

Reliable measurement ensures a continuous supply of raw material

Cost effective

Optimal stocks enable continuous production

User friendly

Maintenance-free operation

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}