First radar level sensor for liquids with 80 GHz

With the smallest antenna of its kind, VEGAPULS 64 is unbeatable for use in small storage or process vessels. Its versatility also makes it ideal for general use across widely different industrial sectors.

Setting new standards with 80 GHz

VEGAPULS 64 operates with a transmission frequency of 80 GHz. With an 80-mm antenna, this results in a beam angle of only 3°. The radar sensor receives only distinct, definitive reflections from the product surface. This makes the measurement more accurate and reliable.

Small but mighty

Messy conditions – so what?

Measurement certainty in all media

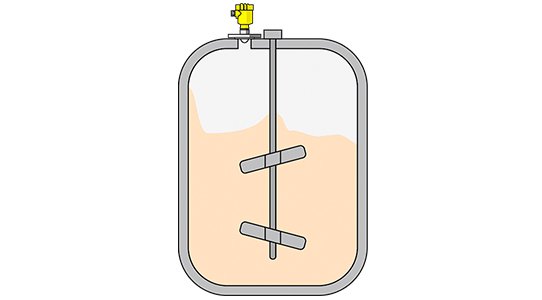

With a dynamic range of 120 dB, VEGAPULS 64 sets new standards for the detection of even the lowest reflected signals. Especially when measuring the level of hydrocarbons that have poor reflective properties, the high dynamics delivers a significantly increased measurement certainty. This means virtually all media in the petrochemical

industry, from crude oil to liquefied gases, can be measured reliably. What is more, the excellent signal focusing enables simple deployment, even when there are heating pipes and other internal vessel structures.

A radar beam with 80 GHz only reflects from the product surface. A wider radar beam with 26 GHz also reflects from internal fixtures and agitators.

A radar beam with 80 GHz only reflects from the product surface. A wider radar beam with 26 GHz also reflects from internal fixtures and agitators.

Sensor version and area of application

|

|

|

|

|

| VEGAPULS 64 in threaded version |

VEGAPULS 64 in flange version |

VEGAPULS 64 with hygienic fittings | VEGAPULS 64 with plastic antenna | |

| Process fitting and beam angle |

Thread G¾, ¾ NPT Thread G1½, 1½ NPT |

Flanges from DN 50, 2" Flanges from DN 80, 3" |

Clamp from 2" |

Collar flange DN 80 |

| Process temperature |

-40 … +200 °C | -40 … +200 °C | -40 … +200 °C Dependent on process fitting |

-40 … +80 °C |

| Process pressure | -1 … +20 bar | -1 … +20 bar | -1 … +16 bar Dependent on process fitting |

-1 … +2 bar |

| Media-contacting materials | Process fittings: 316L Antenna: PEEK Seal: FKM, FFKM |

Antenna: PTFE, PFA | Antenna: PTFE Seal: FKM, EPDM |

Antenna: PP Adapter flange: PPGF 30 Seal: FKM, EPDM Mounting strap: 316L |

| Approvals | ATEX, IEC FM, CSA Ship approvals |

ATEX, IEC FM, CSA FDA, EC 1935/2004 Ship approvals |

ATEX, IEC FM, CSA 3A, EHEDG FDA, EC 1935/2004 |

ATEX, IEC FM, CSA Ship approvals |

Instrument adjustment via smartphone or tablet

A radar beam focused like a laser!

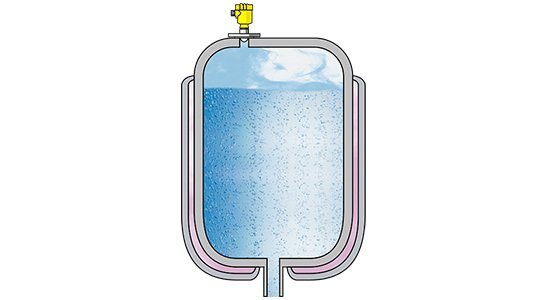

A perfect view – even with condensation!

Close