VEGASWING 66 for deepest cold and extreme heat

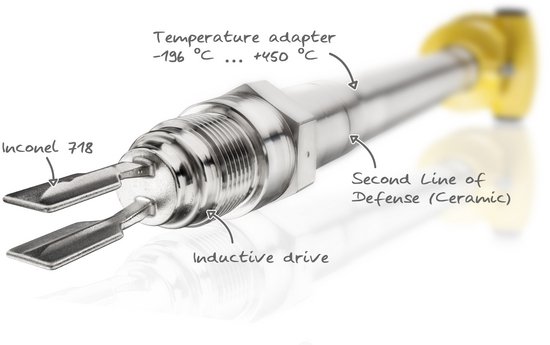

VEGA has extended its level switch portfolio for liquids with VEGASWING 66, the first instrument of its kind in the world. It switches reliably in applications with process temperatures from as low as -196° C, up to +450° C and process pressures up to 160 bar. Integrated analysis and monitoring functions allow certification according to SIL2 and meet EN Steam Boiler regulations.

The new VEGASWING 66 combines all the advantages of vibrating level switches, with a much wider application range!

The new VEGASWING 66 combines all the advantages of vibrating level switches, with a much wider application range!

Reliable and precise switching in liquids

VEGASWING level switches react with a switch signal, the moment the vibration frequency of the tuning fork changes due to contact with a liquid. Four different electronics modules allow simple integration into your system. Since no adjustments have to be made to VEGASWING for setup and commissioning, costly vessel filling can be dispensed with. The level switches are wear and maintenance free – which gives you time for more important tasks.

Connect and go!

The perfect sensor for point level detection, calibration with the product is not required for setup, instead: just connect and go! VEGASWING switches reliably and consistently when a certain filling height is reached, high or low, regardless of the product density, pressure or temperature. Our level switches VEGASWING 61, VEGASWING 63, and of course the new VEGASWING 66, have the following features:

VEGASWING level switches react with a switch signal, the moment the vibration frequency of the tuning fork changes due to contact with a liquid. Four different electronics modules allow simple integration into your system. Since no adjustments have to be made to VEGASWING for setup and commissioning, costly vessel filling can be dispensed with. The level switches are wear and maintenance free – which gives you time for more important tasks.

Connect and go!

The perfect sensor for point level detection, calibration with the product is not required for setup, instead: just connect and go! VEGASWING switches reliably and consistently when a certain filling height is reached, high or low, regardless of the product density, pressure or temperature. Our level switches VEGASWING 61, VEGASWING 63, and of course the new VEGASWING 66, have the following features:

Close