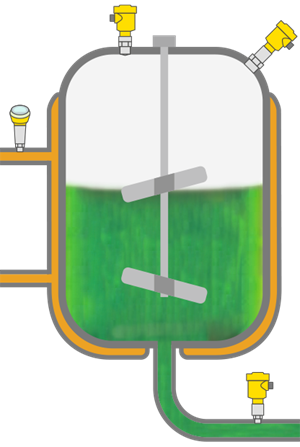

Bioreactor

Level and pressure measurement in the production of enzymes, proteins and antibodies

Process data

Application

Your benefit

Recommended products

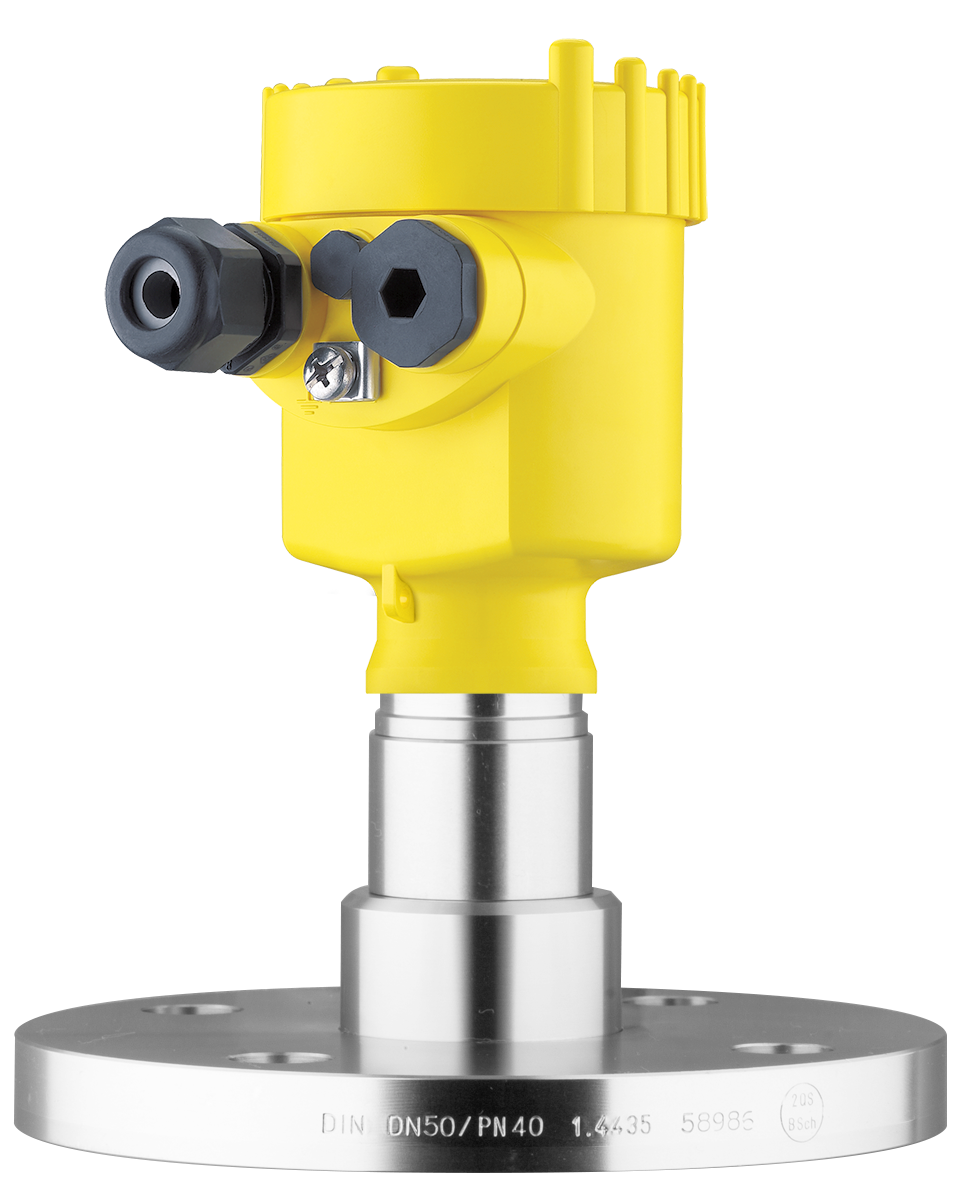

VEGAPULS 6X

Radar sensor for continuous level measurement in the bioreactor

- The front-flush, encapsulated antenna is easy to clean and resistant to the extreme conditions of the SIP and CIP processes

- Maximum utilization of the reactor, measurement is unaffected by changing products and process conditions

- The small beam angle and good focusing of the sensor allows easy alignment

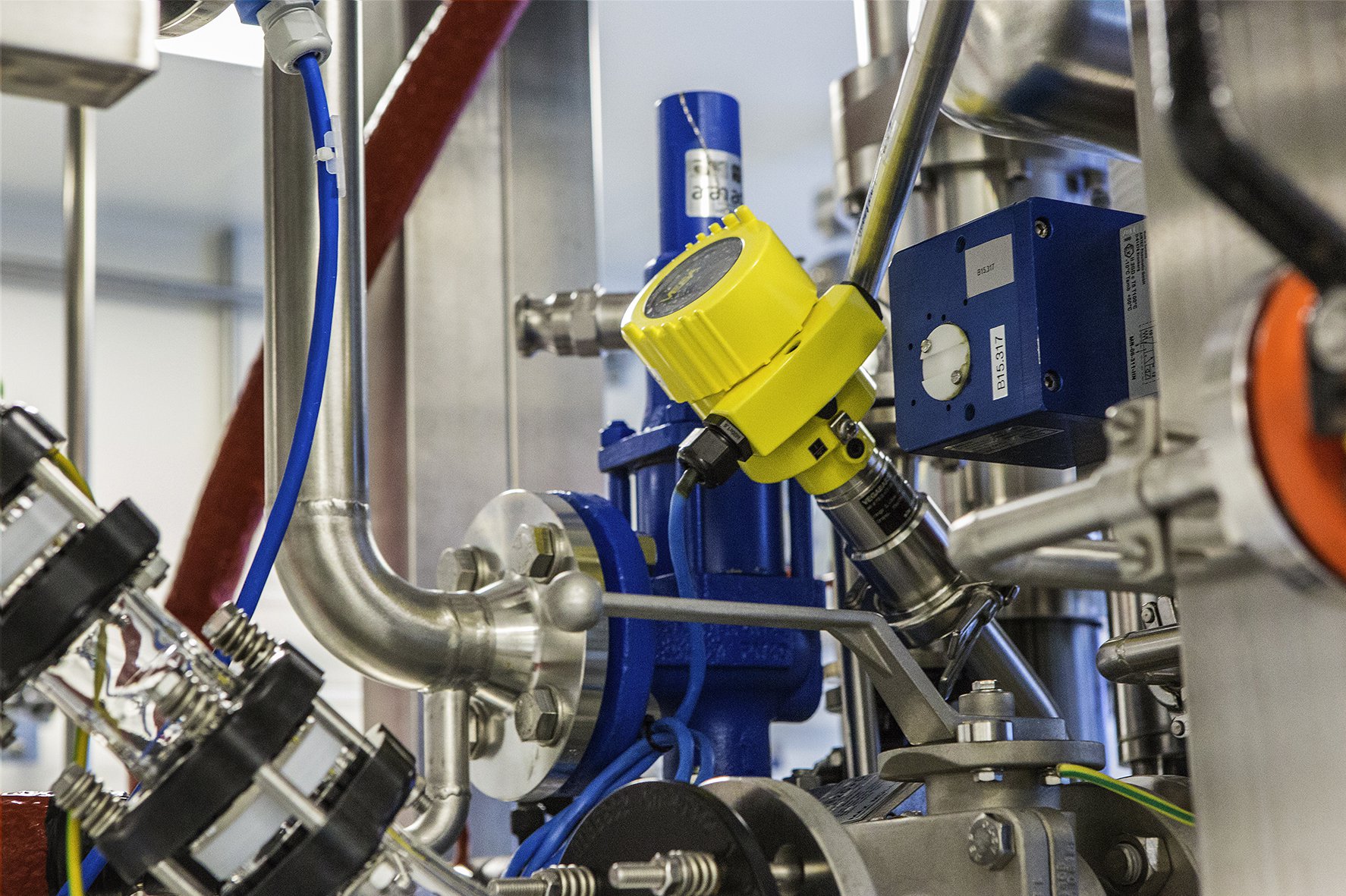

VEGABAR 83

Pressure transmitter for continuous pressure monitoring in the bioreactor and in the pipeline

- The welded, 50 μm-thick Alloy diaphragm with aseptic process fitting is a hygienically optimal and reliable solution

- Neither the chemical cleaning cycles nor the thermal shocks after sterilization can affect the diaphragm

- Pressure measurement in the pipeline for monitoring CIP cleaning processes

VEGABAR 38

Pressure monitoring with IO-Link connection in the supply line of the heating medium

- Reliable measurement thanks to fast response time

- Robust ceramic CERTEC® measuring cell guarantees a long service life

- Simple operation thanks to VDMA menu structure and integrated display

Blog Articles

Close