Entering the digital future of material monitoring with VEGA level transmitters

VEGA level transmitters – decisive added value for plant operators

From simple inventory monitoring to a tailor-made solution

The transmitters were installed at strategic points in the silos. In this application, the expert knowledge of the VEGA employees really paid off. After all, precise level measurement in bulk solids handling systems is a core competence of the instrument manufacturer.

Different models were used, including 55 VEGAPULS 6X for level measurement, a number of VEGAWAVE 62 and VEGAVIB S61 level switches as well as the intrinsically safe VEGATRENN 141 separator.

For visualisation of level data – off to the cloud

The VEGAMET and VEGASCAN controllers collect the signals from the level transmitters and send them pre-processed via a router to VEGA Inventory System in the cloud. From there, the measurement data is made available for visualisation on a dedicated website.

Individual adaptation for precise level measurement

Conclusion

Related industries

Chemical industry

Products

Related posts

State-of-the-art measurement technology for safe chemical logistics: VEGA equips new chemical tank farm with instrumentation

Read more

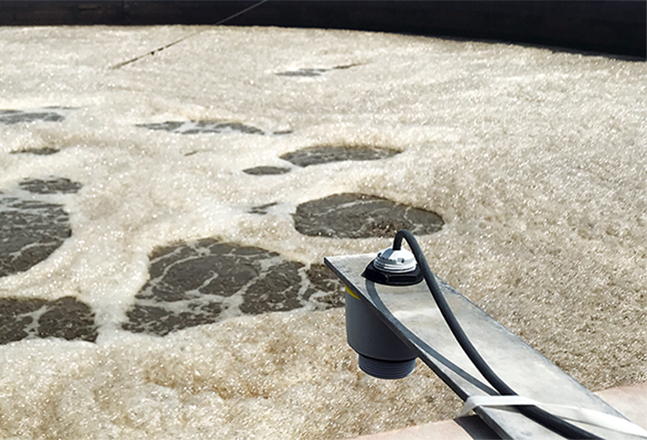

Level and pressure instrumentation for wastewater treatment: High efficiency with VEGA transmitters

Read more

Reliable instruments for challenging applications – How measurement technology secures the chemical industry

Read more

Improve processes in sewage treatment plants with VEGA sensors

Read more

New compact measuring instrument series from VEGA measures process water reliably

Read more

Chemicals distribution 4.0 – Digital transparency through VEGA sensors and VEGA Inventory System

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}